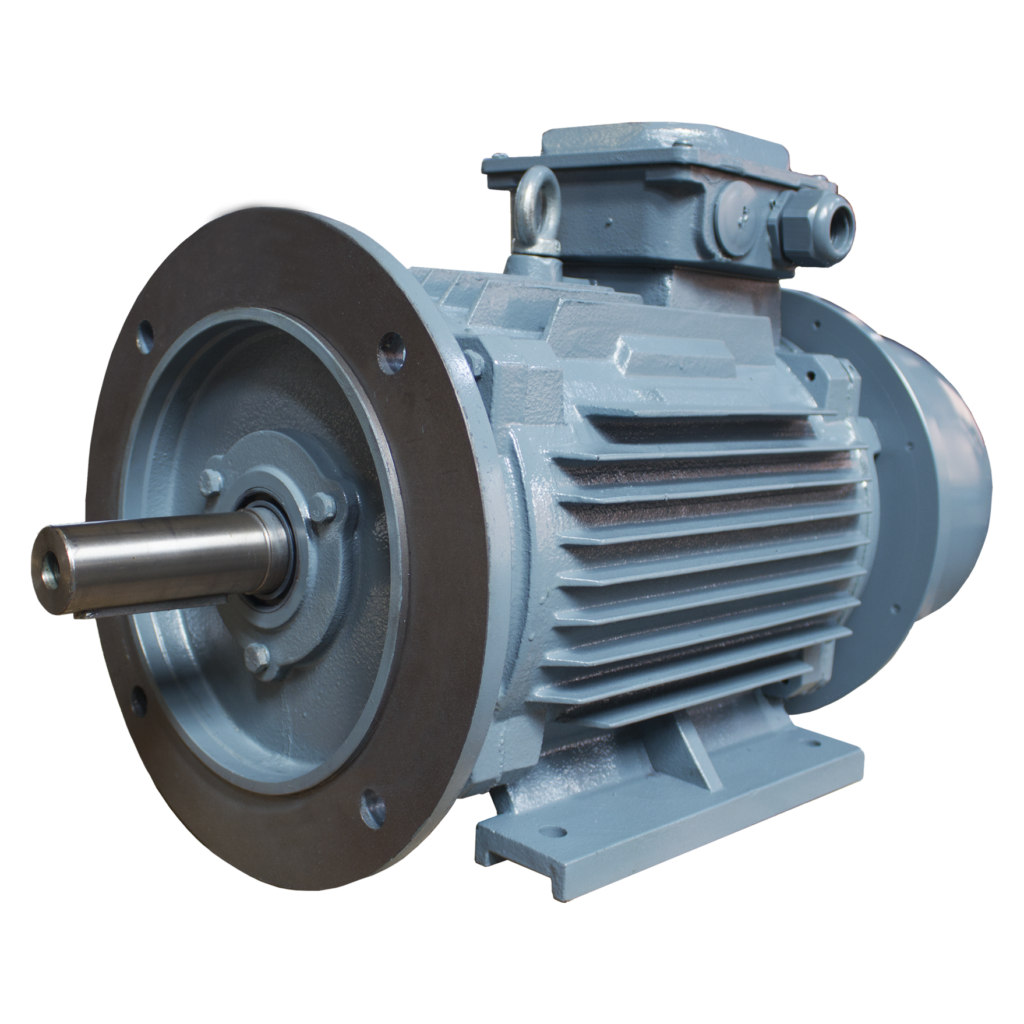

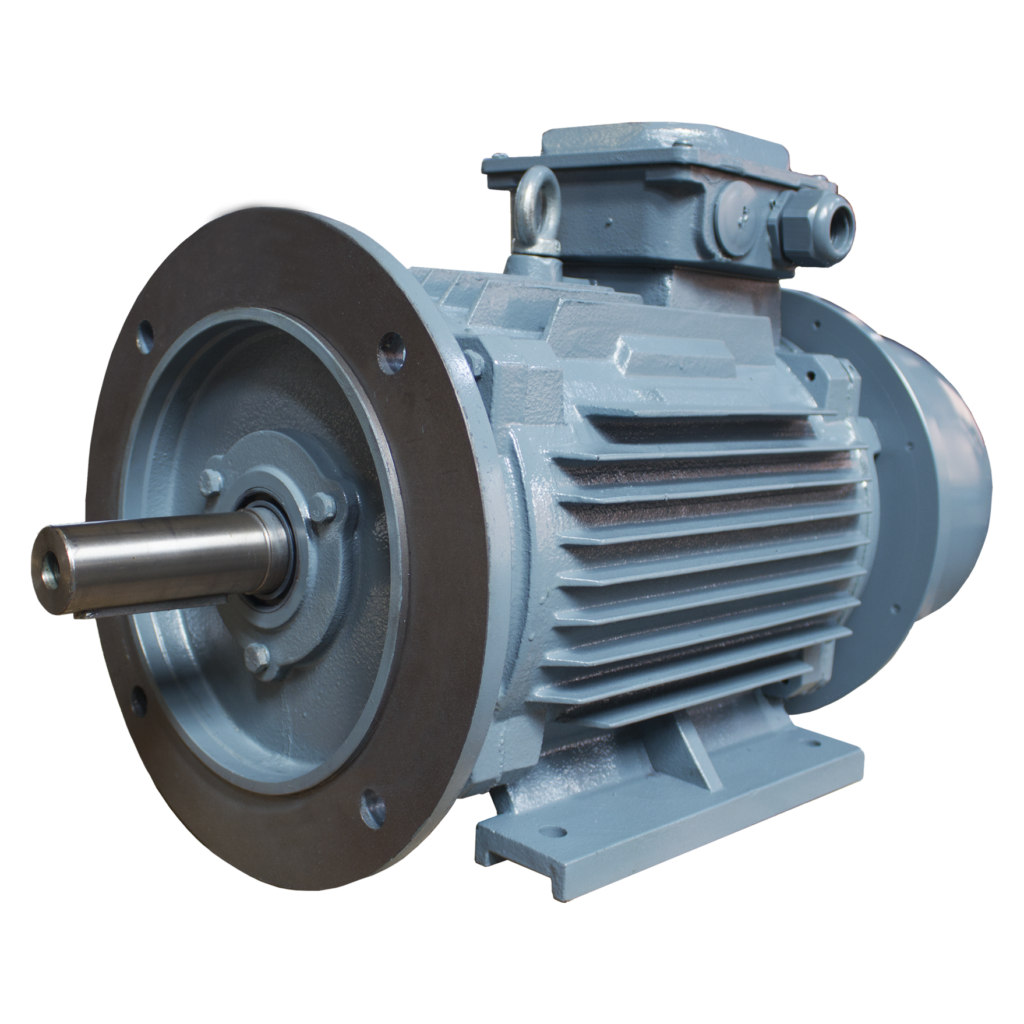

Product Description

Right Angle 6W~40W 60W~370W Induction AC Gear Motor with NMRV Worm Gearbox Speed Reducer

Introduction

1. Lightweight, compact dimension ;

2. Wide speed range and high torque;

3. Low noise and high efficiency;

4. Stable and safe, long lifetime;

5. Multi-structure, various assembling methods;

6. One-stop solution with speed controller, driver, encoder, brake, and transformer available

Specifications

| Greensky Power Right Angle Gear AC Motor | |

| Motor type | Induction motor, brake motor, torque motor, speed adjustable motor, reversible motor |

| Frame size | 80mm, 90mm, 104mm |

| Motor Output speed | 1250rpm – 1500rpm |

| Gearbox Speed Ratio | 1:3 – 1: 100 |

| Output power | 80mm: 25W, 30W

90mm: 40W, 60W, 90W, 120W 104mm: 120W, 140W, 200W, 250W, 370W |

| Output shaft | 12mm ~ 50mm; round shaft, D-cut shaft, key-way shaft, hollow shaft |

| Voltage | 110v, 220v, 230v, 380v |

| Frequency | 50Hz, 60Hz |

Note:

If this model is not what you want, please freely tell us about your requirements. We will provide you with a suitable motor solution and price soon.

FAQ

1 Q: What’s your MOQ for the motor?

A: 1unit is ok for sample testing

2 Q: What about your warranty for your motor?

A: One year.

3 Q: Do you provide OEM service with customer logo?

A: Yes, we could do OEM orders, but we mainly focus on our own brand.

4 Q: How about your payment terms?

A: TT, western union, and PayPal. 100% payment in advance for orders less than $5,000. 30% deposit and balance before delivery for orders over $5,000.

5 Q: How about your packing?

A: Carton, Plywood case. If you need more, we can pack all goods in pallets.

6 Q: What information should be given, if I buy motors from you?

A: Rated power, gearbox ratio, input speed, mounting position. More details, better!

7 Q: How do you deliver the motors?

A: We will compare and choose the most suitable ways of delivery by sea, air or express courier.

We hope you will enjoy cooperating with us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | Single-Phase or Three-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there any emerging trends in brake motor technology, such as digital control?

Yes, there are emerging trends in brake motor technology that are shaping the future of this field. One such trend is the adoption of digital control systems, which offer several advantages over traditional control methods. These advancements in digital control are revolutionizing brake motor technology and unlocking new possibilities for improved performance, efficiency, and integration within industrial processes. Here’s a detailed explanation of the emerging trends in brake motor technology, including the shift towards digital control:

- Digital Control Systems: Digital control systems are becoming increasingly prevalent in brake motor technology. These systems utilize advanced microprocessors, sensors, and software algorithms to provide precise control, monitoring, and diagnostics. Digital control enables enhanced motor performance, optimized energy efficiency, and improved operational flexibility. It allows for seamless integration with other digital systems, such as programmable logic controllers (PLCs) or industrial automation networks, facilitating intelligent and interconnected manufacturing processes.

- Intelligent Motor Control: The integration of digital control systems with brake motors enables intelligent motor control capabilities. These systems use sensor feedback and real-time data analysis to dynamically adjust motor parameters, such as speed, torque, and braking force, based on the changing operating conditions. Intelligent motor control optimizes motor performance, minimizes energy consumption, and enhances overall system efficiency. It also enables predictive maintenance by continuously monitoring motor health and providing early warnings for potential faults or failures.

- Network Connectivity and Industry 4.0: Brake motors are increasingly designed to be part of interconnected networks in line with the principles of Industry 4.0. With digital control systems, brake motors can be connected to industrial networks, enabling real-time data exchange, remote monitoring, and control. This connectivity facilitates centralized monitoring and management of multiple brake motors, improves system coordination, and enables predictive analytics for proactive decision-making. It also allows for seamless integration with other smart devices and systems, paving the way for advanced automation and optimization in manufacturing processes.

- Condition Monitoring and Predictive Maintenance: Digital control systems in brake motors enable advanced condition monitoring and predictive maintenance capabilities. Sensors integrated into the motor can collect data on parameters such as temperature, vibration, and load conditions. This data is processed and analyzed in real-time, allowing for early detection of potential issues or performance deviations. By implementing predictive maintenance strategies, manufacturers can schedule maintenance activities more efficiently, reduce unplanned downtime, and optimize the lifespan and reliability of brake motors.

- Energy Efficiency Optimization: Digital control systems provide enhanced opportunities for optimizing energy efficiency in brake motors. These systems can intelligently adjust motor parameters based on load demand, operating conditions, and energy consumption patterns. Advanced algorithms and control techniques optimize the motor’s energy usage, reducing power wastage and maximizing overall energy efficiency. Digital control also enables integration with energy management systems, allowing for better monitoring and control of energy consumption across the entire manufacturing process.

- Data Analytics and Machine Learning: The integration of digital control systems with brake motors opens up possibilities for leveraging data analytics and machine learning techniques. By collecting and analyzing large volumes of motor performance data, manufacturers can gain valuable insights into process optimization, fault detection, and performance trends. Machine learning algorithms can be applied to identify patterns, predict motor behavior, and optimize control strategies. This data-driven approach enhances decision-making, improves productivity, and enables continuous improvement in manufacturing processes.

In summary, emerging trends in brake motor technology include the adoption of digital control systems, intelligent motor control, network connectivity, condition monitoring, predictive maintenance, energy efficiency optimization, and data analytics. These trends are driving innovation in brake motor technology, improving performance, efficiency, and integration within manufacturing processes. As digital control becomes more prevalent, brake motors are poised to play a vital role in the era of smart manufacturing and industrial automation.

Can you provide examples of machinery or equipment that frequently use brake motors?

In various industrial and manufacturing applications, brake motors are commonly used in a wide range of machinery and equipment. These motors provide braking functionality and enhance the safety and control of rotating machinery. Here are some examples of machinery and equipment that frequently utilize brake motors:

- Conveyor Systems: Brake motors are extensively used in conveyor systems, where they control the movement and stopping of conveyor belts. They ensure smooth and controlled starting, stopping, and positioning of material handling conveyors in industries such as logistics, warehousing, and manufacturing.

- Hoists and Cranes: Brake motors are employed in hoists and cranes to provide reliable load holding and controlled lifting operations. They ensure secure stopping and prevent unintended movement of loads during lifting, lowering, or suspension of heavy objects in construction sites, ports, manufacturing facilities, and other settings.

- Elevators and Lifts: Brake motors are an integral part of elevator and lift systems. They facilitate controlled starting, stopping, and leveling of elevators, ensuring passenger safety and smooth operation in commercial buildings, residential complexes, and other structures.

- Metalworking Machinery: Brake motors are commonly used in metalworking machinery such as lathes, milling machines, and drilling machines. They enable precise control and stopping of rotating spindles, ensuring safe machining operations and preventing accidents caused by uncontrolled rotation.

- Printing and Packaging Machinery: Brake motors are found in printing presses, packaging machines, and labeling equipment. They provide controlled stopping and precise positioning of printing cylinders, rollers, or packaging components, ensuring accurate printing, packaging, and labeling processes.

- Textile Machinery: In textile manufacturing, brake motors are used in various machinery, including spinning machines, looms, and winding machines. They enable controlled stopping and tension control of yarns, threads, or fabrics, enhancing safety and quality in textile production.

- Machine Tools: Brake motors are widely employed in machine tools such as grinders, saws, and machining centers. They enable controlled stopping and tool positioning, ensuring precise machining operations and minimizing the risk of tool breakage or workpiece damage.

- Material Handling Equipment: Brake motors are utilized in material handling equipment such as forklifts, pallet trucks, and automated guided vehicles (AGVs). They provide controlled stopping and holding capabilities, enhancing the safety and stability of load transport and movement within warehouses, distribution centers, and manufacturing facilities.

- Winches and Winders: Brake motors are commonly used in winches and winders for applications such as cable pulling, wire winding, or spooling operations. They ensure controlled stopping, load holding, and precise tension control, contributing to safe and efficient winching or winding processes.

- Industrial Fans and Blowers: Brake motors are employed in industrial fans and blowers used for ventilation, cooling, or air circulation purposes. They provide controlled stopping and prevent the fan or blower from freewheeling when power is turned off, ensuring safe operation and avoiding potential hazards.

These examples represent just a selection of the machinery and equipment where brake motors are frequently utilized. Brake motors are versatile components that enhance safety, control, and performance in numerous industrial applications, ensuring reliable stopping, load holding, and motion control in rotating machinery.

How do brake motors ensure controlled and rapid stopping of rotating equipment?

Brake motors are designed to ensure controlled and rapid stopping of rotating equipment by employing specific braking mechanisms. These mechanisms are integrated into the motor to provide efficient and precise stopping capabilities. Here’s a detailed explanation of how brake motors achieve controlled and rapid stopping:

1. Electromagnetic Brakes: Many brake motors utilize electromagnetic brakes as the primary braking mechanism. These brakes consist of an electromagnetic coil and a brake disc or plate. When the power to the motor is cut off or the motor is de-energized, the electromagnetic coil generates a magnetic field that attracts the brake disc or plate, creating friction and halting the rotation of the motor shaft. The strength of the magnetic field and the design of the brake determine the stopping torque and speed, allowing for controlled and rapid stopping of the rotating equipment.

2. Spring-Loaded Brakes: Some brake motors employ spring-loaded brakes. These brakes consist of a spring that applies pressure on the brake disc or plate to create friction and stop the rotation. When the power is cut off or the motor is de-energized, the spring is released, pressing the brake disc against a stationary surface and generating braking force. The spring-loaded mechanism ensures quick engagement of the brake, resulting in rapid stopping of the rotating equipment.

3. Dynamic Braking: Dynamic braking is another technique used in brake motors to achieve controlled stopping. It involves converting the kinetic energy of the rotating equipment into electrical energy, which is dissipated as heat through a resistor or regenerative braking system. When the power is cut off or the motor is de-energized, the motor acts as a generator, and the electrical energy generated by the rotating equipment is converted into heat through the braking system. This dissipation of energy slows down and stops the rotation of the equipment in a controlled manner.

4. Control Systems: Brake motors are often integrated with control systems that enable precise control over the braking process. These control systems allow for adjustable braking torque, response time, and braking profiles, depending on the specific requirements of the application. By adjusting these parameters, operators can achieve the desired level of control and stopping performance, ensuring both safety and operational efficiency.

5. Coordinated Motor and Brake Design: Brake motors are designed with careful consideration of the motor and brake compatibility. The motor’s characteristics, such as torque, speed, and power rating, are matched with the braking system’s capabilities to ensure optimal performance. This coordinated design ensures that the brake can effectively stop the motor within the desired time frame and with the necessary braking force, achieving controlled and rapid stopping of the rotating equipment.

Overall, brake motors employ electromagnetic brakes, spring-loaded brakes, dynamic braking, and control systems to achieve controlled and rapid stopping of rotating equipment. These braking mechanisms, combined with coordinated motor and brake design, enable precise control over the stopping process, ensuring the safety of operators, protecting equipment from damage, and maintaining operational efficiency.

editor by CX 2024-05-16

China factory 12V 24V 48V 90V DC Right Angle Nmrv Orthogonal Worm Gearbox Reduction Gear Reducer Motor vacuum pump connector

Product Description

12V 24V 48V 90V DC Right Angle Nmrv Orthogonal Worm Gearbox Reduction Gear Reducer BLDC Motor

Features

1) Dimensions: 60*60mm, 70*60mm, 80*80mm, 90*80mm, 90*90mm, 104*90mm

2) Power: 15W 20W 30W 60W 80W 100W 120W 180W 200W 400W

3) Voltage: 12V 24V 48V 90V 310V

4) Rated speed: 2000rpm, 3000rpm

5) Reduction ratio: 3~ 200K

Product Photos

Product Description

| Motor type | Brush type / Brushless type / Stepper type | ||

| Frame size | 16mm ~ 130mm… can be customized | ||

| Running speed | Motor 1500-4000 rpm, Gear Ratio 1/3 ~ 1/3000 | ||

| Output power | 3W ~2200W… can be customized | ||

| Output shaft | round shaft, D-cut shaft, key-way shaft, hollow shaft… | ||

| Voltage type | 12V / 24V / 36V / 48V / 90V / 110V /220V… can be customized | ||

| Accessories | Internal driver / External driver / Connector / Brake / Encoder… | ||

| Gearbox type | Parallel shaft | ||

| Right angle hollow worm shaft | Right angle bevel hollow shaft | Flat type hollow shaft | |

| Right angle CHINAMFG worm shaft | Right angle bevel CHINAMFG shaft | Flat type CHINAMFG shaft | |

| Planetary center shaft | |||

Advantages

Certifications

FAQ

Q: Can you make the gear motor with customization?

A: Yes, we can customize per your request, like power, voltage, speed, shaft size, wires, connectors, IP grade, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What’s your lead time?

A: Standard products need 5-30 days, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, we can provide technical support if you

need.

Q: How to ship to us?

A: It is available by air, by sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with a different currency, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools |

|---|---|

| Operating Speed: | Constant Speed Adjust Speed High Speed Low Speed |

| Excitation Mode: | Excited |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Blue or Silver

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do brake motors ensure smooth and controlled movement in equipment?

Brake motors play a crucial role in ensuring smooth and controlled movement in equipment by providing reliable braking functionality. They work in coordination with the motor and other control systems to achieve precise control over the motion of the equipment. Here’s a detailed explanation of how brake motors ensure smooth and controlled movement in equipment:

- Braking Capability: Brake motors are specifically designed to provide effective braking capability. When the power to the motor is cut off or when a braking signal is applied, the brake system engages, generating frictional forces that slow down and bring the equipment to a controlled stop. The brake torque generated by the motor helps prevent coasting or unintended movement, ensuring smooth and controlled deceleration.

- Quick Response Time: Brake motors are engineered to have a quick response time, meaning that the brake engages rapidly once the control signal is applied. This quick response time allows for prompt and precise control over the movement of the equipment. By minimizing the delay between the initiation of the braking action and the actual engagement of the brake, brake motors contribute to smooth and controlled movement.

- Adjustable Brake Torque: Brake motors often offer the ability to adjust the brake torque to suit the specific requirements of the equipment and application. The brake torque can be tailored to the load characteristics and operating conditions to achieve optimal braking performance. By adjusting the brake torque, brake motors ensure that the equipment decelerates smoothly and consistently, avoiding abrupt stops or jerky movements.

- Brake Release Mechanisms: In addition to providing braking action, brake motors incorporate mechanisms to release the brake when the equipment needs to resume motion. These release mechanisms can be controlled manually or automatically, depending on the application. The controlled release of the brake ensures that the equipment starts moving smoothly and gradually, allowing for controlled acceleration.

- Integration with Control Systems: Brake motors are integrated into the overall control systems of the equipment to achieve coordinated and synchronized movement. They work in conjunction with motor control devices, such as variable frequency drives (VFDs) or servo systems, to precisely control the speed, acceleration, and deceleration of the equipment. By seamlessly integrating with the control systems, brake motors contribute to the smooth and controlled movement of the equipment.

- Compliance with Safety Standards: Brake motors are designed and manufactured in compliance with safety standards and regulations. They undergo rigorous testing and quality control measures to ensure reliable and consistent braking performance. By adhering to safety standards, brake motors help prevent sudden or uncontrolled movements that could pose a safety risk and ensure the equipment operates within acceptable limits.

By providing effective braking capability, quick response time, adjustable brake torque, release mechanisms, integration with control systems, and compliance with safety standards, brake motors ensure smooth and controlled movement in equipment. They enable precise control over the deceleration, stopping, and starting of the equipment, enhancing operational efficiency, safety, and overall performance.

How does a brake motor enhance safety in industrial and manufacturing settings?

In industrial and manufacturing settings, brake motors play a crucial role in enhancing safety by providing reliable braking and control mechanisms. These motors are specifically designed to address safety concerns and mitigate potential risks associated with rotating machinery and equipment. Here’s a detailed explanation of how brake motors enhance safety in industrial and manufacturing settings:

1. Controlled Stopping: Brake motors offer controlled stopping capabilities, allowing for precise and predictable deceleration of rotating machinery. This controlled stopping helps prevent abrupt stops or sudden changes in motion, reducing the risk of accidents, equipment damage, and injury to personnel. By providing smooth and controlled stopping, brake motors enhance safety during machine shutdowns, emergency stops, or power loss situations.

2. Emergency Stop Functionality: Brake motors often incorporate emergency stop functionality as a safety feature. In case of an emergency or hazardous situation, operators can activate the emergency stop function to immediately halt the motor and associated machinery. This rapid and reliable stopping capability helps prevent accidents, injuries, and damage to equipment, providing an essential safety measure in industrial environments.

3. Load Holding Capability: Brake motors have the ability to hold loads in position when the motor is not actively rotating. This load holding capability is particularly important for applications where the load needs to be securely held in place, such as vertical lifting mechanisms or inclined conveyors. By preventing unintended movement or drift of the load, brake motors ensure safe operation and minimize the risk of uncontrolled motion that could lead to accidents or damage.

4. Overload Protection: Brake motors often incorporate overload protection mechanisms to safeguard against excessive loads. These protection features can include thermal overload protection, current limiters, or torque limiters. By detecting and responding to overload conditions, brake motors help prevent motor overheating, component failure, and potential hazards caused by overburdened machinery. This protection enhances the safety of personnel and prevents damage to equipment.

5. Failsafe Braking: Brake motors are designed with failsafe braking systems that ensure reliable braking even in the event of power loss or motor failure. These systems can use spring-loaded brakes or electromagnetic brakes that engage automatically when power is cut off or when a fault is detected. Failsafe braking prevents uncontrolled motion and maintains the position of rotating machinery, reducing the risk of accidents, injury, or damage during power interruptions or motor failures.

6. Integration with Safety Systems: Brake motors can be integrated into safety systems and control architectures to enhance overall safety in industrial settings. They can be connected to safety relays, programmable logic controllers (PLCs), or safety-rated drives to enable advanced safety functionalities such as safe torque off (STO) or safe braking control. This integration ensures that the brake motor operates in compliance with safety standards and facilitates coordinated safety measures across the machinery or production line.

7. Compliance with Safety Standards: Brake motors are designed and manufactured in compliance with industry-specific safety standards and regulations. These standards, such as ISO standards or Machinery Directive requirements, define the safety criteria and performance expectations for rotating machinery. By using brake motors that meet these safety standards, industrial and manufacturing settings can ensure a higher level of safety, regulatory compliance, and risk mitigation.

8. Operator Safety: Brake motors also contribute to operator safety by reducing the risk of unintended movement or hazardous conditions. The controlled stopping and load holding capabilities of brake motors minimize the likelihood of unexpected machine behavior that could endanger operators. Additionally, the incorporation of safety features like emergency stop buttons or remote control options provides operators with convenient means to stop or control the machinery from a safe distance, reducing their exposure to potential hazards.

By providing controlled stopping, emergency stop functionality, load holding capability, overload protection, failsafe braking, integration with safety systems, compliance with safety standards, and operator safety enhancements, brake motors significantly enhance safety in industrial and manufacturing settings. These motors play a critical role in preventing accidents, injuries, and equipment damage, contributing to a safer working environment and ensuring the well-being of personnel.

What industries and applications commonly use brake motors?

Brake motors find wide-ranging applications across various industries that require controlled stopping, load holding, and precise positioning. Here’s a detailed overview of the industries and applications commonly using brake motors:

1. Material Handling: Brake motors are extensively used in material handling equipment such as cranes, hoists, winches, and conveyors. These applications require precise control over the movement of heavy loads, and brake motors provide efficient stopping and holding capabilities, ensuring safe and controlled material handling operations.

2. Elevators and Lifts: The vertical movement of elevators and lifts demands reliable braking systems to hold the load in position during power outages or when not actively driving the movement. Brake motors are employed in elevator systems to ensure passenger safety and prevent unintended movement or freefall of the elevator car.

3. Machine Tools: Brake motors are used in machine tools such as lathes, milling machines, drilling machines, and grinders. These applications often require precise positioning and rapid stopping of rotating spindles or cutting tools. Brake motors provide the necessary control and safety measures for efficient machining operations.

4. Conveyor Systems: Conveyor systems in industries like manufacturing, logistics, and warehouses utilize brake motors to achieve accurate control over the movement of goods. Brake motors enable smooth acceleration, controlled deceleration, and precise stopping of conveyor belts, ensuring proper material flow and minimizing the risk of collisions or product damage.

5. Crushers and Crushers: In industries such as mining, construction, and aggregates, brake motors are commonly used in crushers and crushers. These machines require rapid and controlled stopping to prevent damage caused by excessive vibration or unbalanced loads. Brake motors provide the necessary braking force to halt the rotation of crusher components quickly.

6. Robotics and Automation: Brake motors play a vital role in robotics and automation systems that require precise movement control and positioning. They are employed in robotic arms, automated assembly lines, and pick-and-place systems to achieve accurate and repeatable movements, ensuring seamless operation and high productivity.

7. Printing and Packaging: Brake motors are utilized in printing presses, packaging machines, and labeling equipment. These applications require precise control over the positioning of materials, accurate registration, and consistent stopping during printing or packaging processes. Brake motors ensure reliable performance and enhance the quality of printed and packaged products.

8. Textile Machinery: Brake motors are commonly found in textile machinery such as spinning machines, looms, and textile printing equipment. These applications demand precise control over yarn tension, fabric movement, and position holding. Brake motors offer the necessary braking force and control for smooth textile manufacturing processes.

9. Food Processing: Brake motors are employed in food processing equipment, including mixers, slicers, extruders, and dough handling machines. These applications require precise control over mixing, slicing, and shaping processes, as well as controlled stopping to ensure operator safety and prevent product wastage.

These are just a few examples, and brake motors are utilized in numerous other industries and applications where controlled stopping, load holding, and precise positioning are essential. The versatility and reliability of brake motors make them a preferred choice in various industrial sectors, contributing to enhanced safety, productivity, and operational control.

editor by CX 2024-03-29

China FTG low speed high torque right angle ac gearbox gear motor speed reducer motor driver

Warranty: 3months-1year

Model Number: 4IK60GN-4GN40K

Type: Induction Motor

Frequency: 50

Phase: Single-phase

Protect Feature: Totally Enclosed, Waterproof

AC Voltage: 110V 220V 380V

Efficiency: Ie 3

Certification: ce RoHS

Shell Material: Aluminium

Weight: 3.82kg

Product Type: ac gear motor with gearbox

Product Keywords: FTG 12v low speed high torque dc gearbox gear motor

Application: General Machinery

FTG ac single phase gear motor gearmotor with gearbox diameter60mm 70mm 80mm 90mm 1Whatsapp: MOBILE PHONE: WEBSITE:WWW.FT-MOTOR.COM

Benefits of a Planetary Motor

Besides being one of the most efficient forms of a drive, a Planetary Motor also offers a great number of other benefits. These features enable it to create a vast range of gear reductions, as well as generate higher torques and torque density. Let’s take a closer look at the benefits this mechanism has to offer. To understand what makes it so appealing, we’ll explore the different types of planetary systems.

Solar gear

The solar gear on a planetary motor has two distinct advantages. It produces less noise and heat than a helical gear. Its compact footprint also minimizes noise. It can operate at high speeds without sacrificing efficiency. However, it must be maintained with constant care to operate efficiently. Solar gears can be easily damaged by water and other debris. Solar gears on planetary motors may need to be replaced over time.

A planetary gearbox is composed of a sun gear and two or more planetary ring and spur gears. The sun gear is the primary gear and is driven by the input shaft. The other two gears mesh with the sun gear and engage the stationary ring gear. The three gears are held together by a carrier, which sets the spacing. The output shaft then turns the planetary gears. This creates an output shaft that rotates.

Another advantage of planetary gears is that they can transfer higher torques while being compact. These advantages have led to the creation of solar gears. They can reduce the amount of energy consumed and produce more power. They also provide a longer service life. They are an excellent choice for solar-powered vehicles. But they must be installed by a certified solar energy company. And there are other advantages as well. When you install a solar gear on a planetary motor, the energy produced by the sun will be converted to useful energy.

A solar gear on a planetary motor uses a solar gear to transmit torque from the sun to the planet. This system works on the principle that the sun gear rotates at the same rate as the planet gears. The sun gear has a common design modulus of -Ns/Np. Hence, a 24-tooth sun gear equals a 3-1/2 planet gear ratio. When you consider the efficiency of solar gears on planetary motors, you will be able to determine whether the solar gears are more efficient.

Sun gear

The mechanical arrangement of a planetary motor comprises of two components: a ring gear and a sun gear. The ring gear is fixed to the motor’s output shaft, while the sun gear rolls around and orbits around it. The ring gear and sun gear are linked by a planetary carrier, and the torque they produce is distributed across their teeth. The planetary structure arrangement also reduces backlash, and is critical to achieve a quick start and stop cycle.

When the two planetary gears rotate independently, the sun gear will rotate counterclockwise and the ring-gear will turn in the same direction. The ring-gear assembly is mounted in a carrier. The carrier gear and sun gear are connected to each other by a shaft. The planetary gears and sun gear rotate around each other on the ring-gear carrier to reduce the speed of the output shaft. The planetary gear system can be multiplied or staged to obtain a higher reduction ratio.

A planetary gear motor mimics the planetary rotation system. The input shaft turns a central gear, known as the sun gear, while the planetary gears rotate around a stationary sun gear. The motor’s compact design allows it to be easily mounted to a vehicle, and its low weight makes it ideal for small vehicles. In addition to being highly efficient, a planetary gear motor also offers many other benefits.

A planetary gearbox uses a sun gear to provide torque to the other gears. The planet pinions mesh with an internal tooth ring gear to generate rotation. The carrier also acts as a hub between the input gear and output shaft. The output shaft combines these two components, giving a higher torque. There are three types of planetary gearboxes: the sun gear and a wheel drive planetary gearbox.

Planetary gear

A planetary motor gear works by distributing rotational force along a separating plate and a cylindrical shaft. A shock-absorbing device is included between the separating plate and cylindrical shaft. This depressed portion prevents abrasion wear and foreign particles from entering the device. The separating plate and shaft are positioned coaxially. In this arrangement, the input shaft and output shaft are rotated relative to one another. The rotatable disc absorbs the impact.

Another benefit of a planetary motor gear is its efficiency. Planetary motor gears are highly efficient at transferring power, with 97% of the input energy being transferred to the output. They can also have high gear ratios, and offer low noise and backlash. This design also allows the planetary gearbox to work with electric motors. In addition, planetary gears also have a long service life. The efficiency of planetary gears is due in part to the large number of teeth.

Other benefits of a planetary motor gear include the ease of changing ratios, as well as the reduced safety stock. Unlike other gears, planetary gears don’t require special tools for changing ratios. They are used in numerous industries, and share parts across multiple sizes. This means that they are cost-effective to produce and require less safety stock. They can withstand high shock and wear, and are also compact. If you’re looking for a planetary motor gear, you’ve come to the right place.

The axial end surface of a planetary gear can be worn down by abrasion with a separating plate. In addition, foreign particles may enter the planetary gear device. These particles can damage the gears or even cause noise. As a result, you should check planetary gears for damage and wear. If you’re looking for a gear, make sure it has been thoroughly tested and installed by a professional.

Planetary gearbox

A planetary motor and gearbox are a common combination of electric and mechanical power sources. They share the load of rotation between multiple gear teeth to increase the torque capacity. This design is also more rigid, with low backlash that can be as low as one or two arc minutes. The advantages of a planetary gearmotor over a conventional electric motor include compact size, high efficiency, and less risk of gear failure. Planetary gear motors are also more reliable and durable than conventional electric motors.

A planetary gearbox is designed for a single stage of reduction, or a multiple-stage unit can be built with several individual cartridges. Gear ratios may also be selected according to user preference, either to face mount the output stage or to use a 5mm hex shaft. For multi-stage planetary gearboxes, there are a variety of different options available. These include high-efficiency planetary gearboxes that achieve a 98% efficiency at single reduction. In addition, they are noiseless, and reduce heat loss.

A planetary gearbox may be used to increase torque in a robot or other automated system. There are different types of planetary gear sets available, including gearboxes with sliding or rolling sections. When choosing a planetary gearset, consider the environment and other factors such as backlash, torque, and ratio. There are many advantages to a planetary gearbox and the benefits and drawbacks associated with it.

Planetary gearboxes are similar to those in a solar system. They feature a central sun gear in the middle, two or more outer gears, and a ring gear at the output. The planetary gears rotate in a ring-like structure around a stationary sun gear. When the gears are engaged, they are connected by a carrier that is fixed to the machine’s shaft.

Planetary gear motor

Planetary gear motors reduce the rotational speed of an armature by one or more times. The reduction ratio depends on the structure of the planetary gear device. The planetary gear device has an output shaft and an armature shaft. A separating plate separates the two. The output shaft moves in a circular pattern to turn the pinion 3. When the pinion rotates to the engagement position, it is engaged with the ring gear 4. The ring gear then transmits the rotational torque to the armature shaft. The result is that the engine cranks up.

Planetary gear motors are cylindrical in shape and are available in various power levels. They are typically made of steel or brass and contain multiple gears that share the load. These motors can handle massive power transfers. The planetary gear drive, on the other hand, requires more components, such as a sun’s gear and multiple planetary gears. Consequently, it may not be suitable for all types of applications. Therefore, the planetary gear drive is generally used for more complex machines.

Brush dusts from the electric motor may enter the planetary gear device and cause it to malfunction. In addition, abrasion wear on the separating plate can affect the gear engagement of the planetary gear device. If this occurs, the gears will not engage properly and may make noise. In order to prevent such a situation from occurring, it is important to regularly inspect planetary gear motors and their abrasion-resistant separating plates.

Planetary gear motors come in many different power levels and sizes. These motors are usually cylindrical in shape and are made of steel, brass, plastic, or a combination of both materials. A planetary gear motor can be used in applications where space is an issue. This motor also allows for low gearings in small spaces. The planetary gearing allows for large amounts of power transfer. The output shaft size is dependent on the gear ratio and the motor speed.

editor by czh

China OEM Right Angle Gear Dc SPORTS MACHINE motor used for Training Fitness Equipments, Option with dual hollow shaft with Free Design Custom

Warranty: 3years

Model Number: 63WG

Usage: Home Appliance

Type: GEAR MOTOR

Torque: customed

Construction: Permanent Magnet

Commutation: Brush

Protect Feature: Drip-proof

Speed(RPM): customed

Continuous Current(A): customed

Efficiency: IE 1

Certification: ce

Certification 2: RoHS

Packaging Details: standard export package

Port: ZheJiang

63WG.63ZYT SERIES PM DC WORM GEAR MOTOR

Motor Specifications:

Bearing: High Quality Ball Bearing

Magnet: Hard Ferrite Magnet, 2- Poles

Protection Class: IP50 (Option for IP54)

Insulation Class: Class F / Working Temperature: -40℃~+140℃

Motor Main Characteristics:

Model

Unit

63ZYT01A/01L

63ZYT02A/02L

63ZYT03A/03L

Rated Voltage

VDC

24v (option for 12v up to 48vdc)

Rated Speed

Rpm

3100

1550

3000

1800

3000

2000

Rated Torque

N.m

0.15

0.12

0.31

0.25

0.41

0.35

No Load Speed

Rpm

3600

1800

3500

2400

3500

2600

Weight

Kg

1

1

1.2

1.2

1.35

1.35

Motor Length

Mm

95

95

110

110

125

125

Output Power

W

50

19

98

47

129

73

63WG Series Worm Gearbox Specifications:

Reduction ratio

10

15

30

Efficiency

0.65

0.55

0.45

Continuous torque

Ncm

Up to 1000(metallic gears) / Up to 400(non-metallic gears)

Weight of gearbox

kg

0.4

Axial load/radial load

N

300/350

Hollow shaft version

double shaft version

Brushless version

How to Assemble a Planetary Motor

A Planetary Motor uses multiple planetary surfaces to produce torque and rotational speed. The planetary system allows for a wide range of gear reductions. Planetary systems are particularly effective in applications where higher torques and torque density are needed. As such, they are a popular choice for electric vehicles and other applications where high-speed mobility is required. Nevertheless, there are many benefits associated with using a planetary motor. Read on to learn more about these motors.

VPLite

If you’re looking to replace the original VP, the VPLite has a similar output shaft as the original. This means that you can mix and match your original gear sets, including the input and output shafts. You can even mix metal inputs with plastic outputs. Moreover, if you decide to replace the gearbox, you can easily disassemble the entire unit and replace it with a new one without losing any output torque.

Compared to a planetary motor, a spur gear motor uses fewer gears and is therefore cheaper to produce. However, the latter isn’t suitable for high-torque applications. The torque produced by a planetary gearmotor is evenly distributed, which makes it ideal for applications that require higher torque. However, you may have to compromise on the torque output if you’re looking for a lightweight option.

The VersaPlanetary Lite gearbox replaces the aluminum ring gear with a 30% glass-filled nylon gear. This gearbox is available in two sizes, which means you can mix and match parts to get a better gear ratio. The VPLite gearbox also has a female 5mm hex output shaft. You can mix and match different gearboxes and planetary gearboxes for maximum efficiency.

VersaPlanetary

The VersaPlanetary is a highly versatile planetary motor that can be mounted in a variety of ways. Its unique design includes a removable shaft coupler system that makes it simple to swap out the motor with another. This planetary motor mounts in any position where a CIM motor mounts. Here’s how to assemble the motor. First, remove the hex output shaft from the VersaPlanetary output stage. Its single ring clip holds it in place. You can use a drill press to drill a hole into the output shaft.

After mounting the gearbox, you can then mount the motor. The mounting hardware included with the VersaPlanetary Planetary Motor comes with four 10-32 threaded holes on a two-inch bolt circle. You can use these holes to mount your VersaPlanetary on a CIM motor or a CIM-compatible motor. Once assembled, the VersaPlanetary gearbox has 72 different gear ratios.

The VersaPlanetary gearbox is interchangeable with regular planetary gearboxes. However, it does require additional parts. You can purchase a gearbox without the motor but you’ll need a pinion. The pinion attaches to the shaft of the motor. The gearbox is very sturdy and durable, so you won’t have to worry about it breaking or wearing out.

Self-centering planetary gears

A planetary motor is a simple mechanical device that rotates around a axis, with the planets moving around the shaft in a radial direction. The planets are positioned so that they mesh with both the sun gear and the output gears. The carrier 48 is flexibly connected to the drive shaft and can move depending on the forces exerted by the planet gears. In this way, the planets can always be in the optimal mesh with the output gears and sun gear.

The first step in developing a planetary gear motor is to identify the number of teeth in each planet. The number of teeth should be an integer. The tooth diameters of the planets should mesh with each other and the ring. Typically, the teeth of one planet must mesh with each other, but the spacing between them must be equal or greater than the other. This can be achieved by considering the tooth count of each planet, as well as the spacing between planets.

A second step is to align the planet gears with the output gears. In a planetary motor, self-centering planetary gears must be aligned with both input and output gears to provide maximum torque. For this to be possible, the planet gears must be connected with the output shaft and the input shaft. Similarly, the output shaft should also be able to align with the input gear.

Encoders

A planetary geared motor is a DC motor with a planetary gearbox. The motor can be used to drive heavy loads and has a ratio of 104:1. The shaft speed is 116rpm when it is unloaded. A planetary gearbox has a low backlash and is often used in applications that need high torque. Planetary Motor encoders can help you keep track of your robot’s position or speed.

They are also able to control motor position and speed with precision. Most of them feature high resolution. A 0.18-degree resolution encoder will give you a minimum of 2000 transitions per rotation between outputs A and B. The encoder is built to industrial standards and has a sturdy gearbox to avoid damage. The encoder’s robust design means it will not stall when the motor reaches its maximum speed.

There are many advantages to a planetary motor encoder. A high-quality one will not lose its position or speed even if it’s subject to shocks. A good quality planetary motor will also last a long time. Planetary motors are great for resale or for your own project. If you’re considering buying a planetary motor, consider this information. It’ll help you decide if a particular model is right for your needs.

Cost

There are several advantages of planetary motors. One of the biggest is their cost, but they can also be used in many different applications. They can be combined with a variety of gearboxes, and are ideal for various types of robots, laboratory automation, and production applications. Planetary gearboxes are available in many different materials, and plastic planetary gearboxes are an economical alternative. Plastic gearboxes reduce noise at higher speeds, and steel input stage gears are available for high torques. A modified lubrication system can help with difficult operating conditions.

In addition to being more durable, planetary motors are much more efficient. They use fewer gears, which lowers the overall cost of production. Depending on the application, a planetary motor can be used to move a heavy object, but is generally less expensive than its counterpart. It is a better choice for situations where the load is relatively low and the motor is not used frequently. If you need a very high torque output, a planetary motor may be the better option.

Planetary gear units are a good choice for applications requiring high precision, high dynamics, and high torque density. They can be designed and built using TwinCAT and TC Motion Designer, and are delivered as complete motor and gear unit assemblies. In a few simple steps, you can calculate the torque required and compare the costs of different planetary gear units. You can then choose the best model for your application. And because planetary gear units are so efficient, they are a great option for high-end industrial applications.

Applications

There are several different applications of the planetary motor. One such application is in motion control. Planetary gearboxes have many benefits, including high torque, low backlash, and torsional stiffness. They also have an extremely compact design, and can be used for a variety of applications, from rack and pinion drives to delta robotics. In many cases, they are less expensive to manufacture and use than other types of motors.

Another application for planetary gear units is in rotary tables. These machines require high precision and low backlash for their precise positioning. Planetary gears are also necessary for noise reduction, which is a common feature in rotary tables. High precision planetary gears can make the height adjustment of OP tables a breeze. And because they are extremely durable and require low noise, they are a great choice for this application. In this case, the planetary gear is matched with an AM8000 series servomotor, which gives a wide range of choices.

The planetary gear transmission is also widely used in helicopters, automobiles, and marine applications. It is more advanced than a countershaft drive, and is capable of higher torque to weight ratios. Other advantages include its compact design and reduced noise. A key concern in the development of this type of transmission is to minimize vibration. If the output of a planetary gear transmission system is loud, the vibration caused by this type of drive system may be too loud for comfort.

in Novokuznetsk Russian Federation sales price shop near me near me shop factory supplier Atg High Stability Right Angle Planetary Reducer for DC Motor Gearbox manufacturer best Cost Custom Cheap wholesaler

we provide chromed bar and tubes for hydualic and pheumatic cylinders. Our products are applied in a lot of fields. we offer you one-cease solution for the obtain of mechanical electricity transmission products in China. PGRH Collection

Products Characteristics:

(1) Lower Noise:UnEPT65db.

(2) Low Backlash:Backlash is unEPT3 arcmin . Backlash for two-stage pace reduction is with in five arcmin.

(3) High Efficiency:1-phase up to ninety five% or far more,two-phase up to ninety two% or far more.

(four) High Input Pace:Enter velocity makes it possible for for up to 8000RPM.

(five) Substantial Torque:Substantial torque output than that of standard planetary EPT EPTs

(six) Upkeep-Cost-free:Reduced grease put on,can be life span lubrication

(7) High Speed Reduction Ratio:Velocity ratio is more than 1/1000.

Benefit:

Usage:

- Aerospace,navy market.

- Health care overall health,electronic info business.

- Business robots,Generation EPT,CNC EPT device production sector.

- EPT,Textile,EPT,Foods,EPTlurgical.

- EPT safety engineering,Warehouse EPT market.

Design ILLUMINATE:

Gear BOX Efficiency Details:

| MODUL NO. | Phase | RATIO sup1 | PGRH42 | PGRH60 | PGRH90 | PGRH115 | PGRH142 | PGRH180 | PGRH220 | |

| Rated output torque T2N | Nm | 1 | three | twenty | 55 | a hundred thirty | 208 | 342 | 588 | one,140 |

| 4 | 19 | 50 | 140 | 290 | 542 | one,050 | 1,seven-hundred | |||

| five | 22 | 60 | 160 | 330 | 650 | 1,two hundred | 2,000 | |||

| six | twenty | fifty five | 150 | 310 | 600 | 1,one hundred | one,900 | |||

| seven | 19 | 35 | one hundred forty | three hundred | 550 | one,a hundred | one,800 | |||

| eight | 17 | 35 | 120 | 260 | 500 | 1,000 | 1,600 | |||

| ten | fourteen | 37 | 95 | 220 | 370 | 800 | one,220 | |||

| 14 | – | 35 | one hundred forty | three hundred | 550 | 1,one hundred | 1,800 | |||

| twenty | – | 37 | 95 | 220 | 370 | 800 | one,220 | |||

| two | fifteen | twenty | 50 | one hundred thirty | 208 | 342 | 588 | 1,a hundred and forty | ||

| twenty | 19 | 60 | one hundred forty | 290 | 542 | one,050 | one,seven-hundred | |||

| twenty five | 22 | 60 | a hundred and sixty | 330 | 650 | 1,200 | 2,000 | |||

| thirty | 22 | 60 | one hundred sixty | 330 | 650 | 1,two hundred | 2,000 | |||

| 35 | 22 | sixty | one hundred sixty | 330 | 650 | one,200 | 2,000 | |||

| forty | 22 | 60 | a hundred and sixty | 330 | 650 | 1,two hundred | two,000 | |||

| 50 | 22 | 60 | one hundred sixty | 330 | 650 | one,200 | two,000 | |||

| 60 | 22 | sixty | one hundred sixty | 330 | 650 | one,200 | 2,000 | |||

| 70 | 22 | sixty | a hundred and sixty | 330 | 650 | 1,two hundred | two,000 | |||

| 80 | 22 | 60 | a hundred and sixty | 330 | 650 | 1,200 | two,000 | |||

| 100 | 22 | sixty | ninety five | 220 | 370 | 800 | 1,220 | |||

| 120 | – | – | 150 | 310 | 600 | one,one hundred | 1,900 | |||

| one hundred forty | – | – | one hundred forty | 300 | 550 | one,one hundred | 1,800 | |||

| 160 | – | – | a hundred and twenty | 260 | 500 | 1,000 | one,600 | |||

| 200 | – | – | 48 | one hundred forty | 370 | 520 | 1,220 | |||

| MAX. output torqueT2B | Nm | one,two | three~two hundred | three instances of Nominal Output Torque | ||||||

| Rated input velocity n1 | rpm | one,two | 3~200 | 5,000 | five,000 | four,000 | 4,000 | three,000 | three,000 | two,000 |

| MAX.input speed n1B | rpm | 1,2 | three~two hundred | ten,000 | 10,000 | 8,000 | 8,000 | 6,000 | 6,000 | four,000 |

| Micro Backlash P0 | arcmin | 1 | 3~twenty | – | – | le2 | le2 | le2 | le2 | le2 |

| 2 | fifteen~200 | – | – | le4 | le4 | le4 | le4 | le4 | ||

| EPT Backlash P1 | arcmin | 1 | three~20 | le4 | le4 | le4 | le4 | le4 | le4 | le4 |

| two | fifteen~two hundred | le7 | le7 | le7 | le7 | le7 | le7 | le7 | ||

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Backlash P2 | arcmin | one | three~20 | le6 | le6 | le6 | le6 | le6 | le6 | le6 |

| two | 15~200 | le9 | le9 | le9 | le9 | le9 | le9 | le9 | ||

| Torsional stiffness | Nm/arcmin | one,two | 3~two hundred | 3 | seven | fourteen | twenty five | 50 | 145 | 225 |

| Max.radial drive F2rB sup2 | N | 1,two | 3~200 | 780 | one,530 | 3,250 | six,700 | 9,400 | 14,five hundred | fifty,000 |

| MAX.aXiHu (West Lake) Dis.al force F2a1B sup2 | N | one,two | 3~200 | 350 | 630 | one,300 | three,000 | 4,000 | 6,200 | 35,000 |

| MAX.aXiHu (West Lake) Dis.al pressure F2a2B sup2 | N | one,two | 3~200 | 390 | 765 | 1,625 | 3,350 | 4,700 | 7,250 | 25,000 |

| Service lifestyle | hr | 1,two | 3~200 | twenty,000* | ||||||

| Operate effectiveness eta | % | 1 | 3~20 | ge97 | ||||||

| two | 15~200 | ge94 | ||||||||

| Fat | kg | one | 3~twenty | .9 | 2.one | six.four | thirteen | 24.5 | 51 | eighty three |

| 2 | fifteen~two hundred | 1.2 | 1.5 | 7.8 | fourteen.two | 27.5 | 54 | ninety five | ||

| Operating temperature | ordmC | one,two | three~two hundred | -10 ordmC~ ninety ordmC | ||||||

| Lubrication | 1,two | 3~200 | Artificial lubricating oil | |||||||

| Security amount | 1,2 | 3~two hundred | IP65 | |||||||

| Set up path | one,two | 3~two hundred | Any path | |||||||

| Sound degree(n1=3000rpm) | dB | 1,2 | 3~200 | le61 | le63 | le65 | le68 | le70 | le72 | le74 |

Define DIMENSION:

Firm See:

HangEPT EPEPTndeyi EPT amp Electrical Co., Ltd. is a subsidiary of EPTiwan Jun Yi EPTry. Jun Yi EPTry was established in March 1972. The company EPTizes in the layout, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and generation of large-tech different EPTed motors and helical EPT EPTs, worm and worm EPT EPTs and planetary EPTs. Our items offered to far more than 30 nations around the world around the world and acquire excellent track record and numerous awards in the overEPT industry for a lot of many years. In current years, to accomplish EPT production and supply exceptional support,we established up subsidiary of production of planetary EPT EPT in EPT.

Heritage:

1972:EPTiwan Jun Yi EPTry is started.

1989:It estabEPTd a overEPT branch firm ATRUMP EPTRY INC in Los Angeles

1995:Go the ISO9002 Commodity certification.

2003:Move the ISO9001 good quality certification and the European CE stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd examination which enabled the goods to be sold in Europe

2013:The firm established up subsidiary in EPT to achieve EPT manufacturing.

Manufacturing unit:

Wisdom Created In ATG,Wisdom The EPT.

Equipment:

INSPECTION Tools:

FAQ:

(one) Can I be your agent?

Indeed, welcome to deep cooperation. We have massive promotion of ATG brand in the market now. For the details remember to speak to me.

(two) Is OEM available?

Yes, OEM is accessible. We have skilled designer to help your manufacturer marketing.

(3) How can I get a sample to verify your high quality?

Right after price affirmation, you can demand for samples to examine our quality. Totally free for the samples, but you need to have to pay for the freight.

(4)What is actually your quality ensure?

We have different types of products which can meet various high quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Our QC department will check items just before shipping. We have a hundred% good quality assure to consumers. We will be accountable for any high quality problem.

(5) How about the supply time?

The shipping and delivery time is dependent on the products and the amount. But EPTly, the supply time for a container is about one particular thirty day period.

Welcome to our firm.

If any dilemma, feel free to depart concept on the base of this page.

in Bucheon Republic of Korea sales price shop near me near me shop factory supplier 80mm Solid Right Angle Micro AC Gear Motor 25W High Torque Speed Control Motor manufacturer best Cost Custom Cheap wholesaler

The higher specific CNC products, this kind of as Sluggish-feeding wire-reduce equipment, jig grinding machine and electric powered discharge device, guarantees the best top quality precision of mould processing, with the substantial effective and environmental safety acid rolling line getting the greatest uncooked content converting gear in the field in china The wildly use of automatic milling machine, substantial-speed computerized feeding punch, large pace computerized rolling and assembling device assures the substantial good quality and effectiveness of elements and chain making. a specialised provider of a complete selection of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers. We are hunting forward to establishing effective company interactions with new consumers all around the entire world in the future.

Solution specifications

The adhering to are the requirements that our firm’s Micro AC EPT motors 25w can accomplished. You can also make contact with us to notify us the EPT, voltage, torque and other parameters you need to have. We can settle for and personalize. and You can also contact us for drawings and in depth parameters.

| Band name | EPT |

| Out EPT | 25w |

| Dimension | 80mm |

| Voltage | 110v 220v 230v 380v |

| Frequency | 50Hz 60Hz |

| Section | Single phase |

| Gear ratio | five-2250 |

| Max ratio with decimal EPThead | 7500 |

| EPT Shaft sort | Hollow / Strong / Eccentric shaft / Central shaft |

| Accessories that can be included | EPT box Terminal box w/fan w/ pressured fan eleceromagnetic brake thermally |

| Micro ac EPT motor sort | Induction motor Reversible motor Torque motor Velocity management motor RigEPT angle EPT motor Brake motor |

Item Functions:

Large effectiveness

Large torque Low pace

Lower sounds EPT life EPT reliability

Managing easily

Brushless environmental defense

Basic composition straightforward to use

Factory provider best value

Ideal for intense environments

Broad selection of applications

item drawings

item specifics

one.AC Gear EPT

Compact composition, good sealing efficiency, minimal noise, EPT lifestyle,reduced functioning temperature Adjustable pace, reversible, EPT and reverse

2.All Copper Coil

All copper coil, quick heat dissipation, daily life is 10 times that of normal coil

3.Large precision difficult tooth surface

The EPT has high precision, higher hardness, anti-rust therapy, water-resistant and quiet, EPT lifestyle

Application

AC EPT motor widely used in EPT gear, EPT resources, agricultural EPTs, business business office, medical tools, EPT EPTs, aviation and other fields. This sort of as treadmill, stitching EPT, meat grinEPT, tortilla press maker, Attire EPT, Textile EPT, EPT Coating EPTry, EPTs, Sprayers, heavy EPT tools, EPT EPT, nebulizer, desk admirer, Experience Mask EPT, Rehabilitation Therapy EPT, fridge, Air Purifiers, Fermenting EPT. and numerous much more.

Organization Certifaction

About us:

ZheJiang EPT EPT Co., Restricted. company, is the recognized best producer of EPT humidification method inEPT. Our factory has a few large workshops, masking three,000 sq. meter region. We have far more than 100 workers, equip with specialist R ampD staff, reliable employees and successful revenue provider staff. Inexperienced target on study and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment, manufacture, and sale of humidifying, air cooling, dedusting, dehumidifying and power preserving equipment. Our organization is evolving as the alter of customers’ demands, we are committed to deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ing and engineering new EPT to best match our customers’ needs. So far, we have got several patents on extremely EPT and successful humidifier styles.Operating with Green, you will enEPT the most recent and most EPT EPT and kindest support.

Our Mine Product:

DC/AC motor, stepper motor, EPT, CNC engraving EPT, EPT humidifier.

Our Providers:

Every of our goods will endure demanding testing prior to leaving the manufacturing facility. We will supply you with professional types and solutions, high-quality goods and substantial-quality solutions in accordance to your needs. If you have any queries, make sure you really feel cost-free to

contact us. We will serve you quickly.

EPT ampEPT

Inside : Plastic baggage with Chemical Desiccant For Equipment EPT

Middle : Individual Carton EPT Exterior : EPTen Box

Shipment: TNT, DHL, UPS, FedEx,EMS and many others.Or use the cargo your specified.

Strict merchandise EPT assures that the solution is not damaged in the course of transportation.

FAQ

Q1 Are you a manufacturer or a trading company?

We are a motor in EPT.

Q2 What is actually your guarantee?

A single-yr.

Q3 Can you give far more discount rates if more quantity and how many?

We can find the money for discounts and fee primarily based on updated quantity.

This fall Can you make OEM/ODM order?

Sure, we have abundant knowledge on OEM/ODM purchase.

Q5 Shipping and delivery

Sample can be afforded in five-7daEPTand volume orEPTcan be finished in fifteen-20days.

Q6 About sample?

Accessible.

Q7 Which of payments you assist?

T/T, L/C,PAYPAL, Credit CARD.

Q8 Which of transportations you assistance?

Sea, Air cargo, Practice, DHL/FEDEX/UPS/TNT.

Q9 What you can do if we even now have be concerned on your item?

We can afford sample for testing, if approval then negotiate cooperation later on.