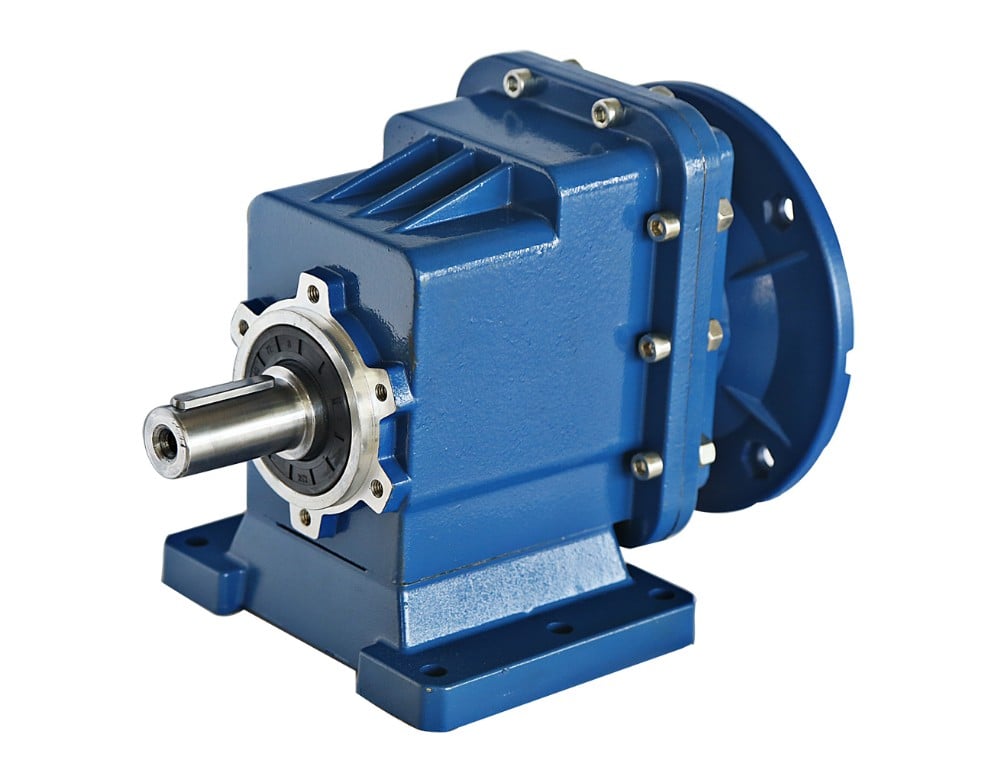

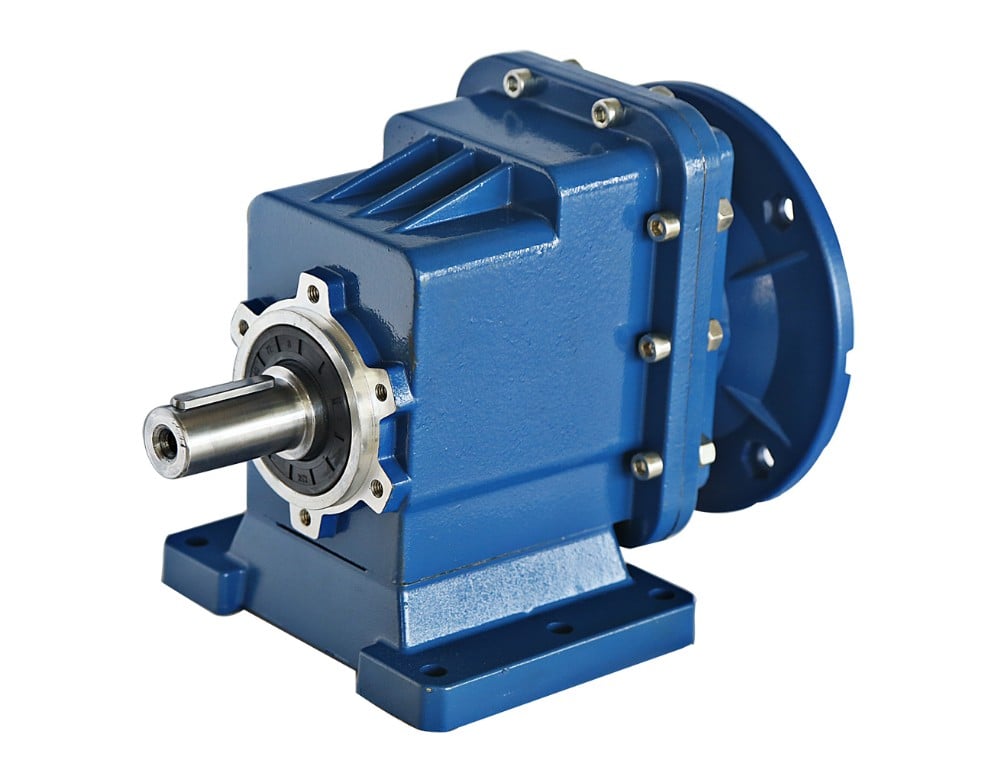

Product Description

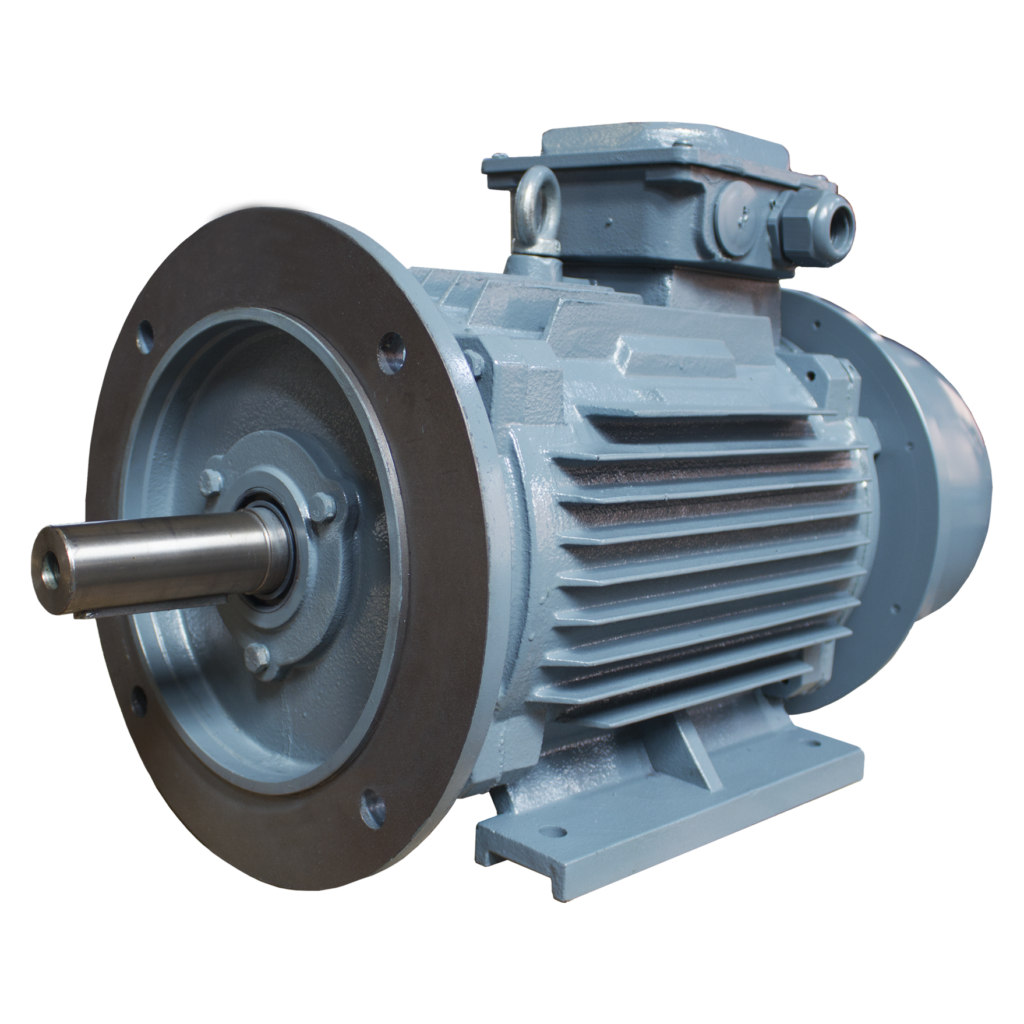

Right Angle 6W~40W 60W~370W Induction AC Gear Motor with NMRV Worm Gearbox Speed Reducer

Introduction

1. Lightweight, compact dimension ;

2. Wide speed range and high torque;

3. Low noise and high efficiency;

4. Stable and safe, long lifetime;

5. Multi-structure, various assembling methods;

6. One-stop solution with speed controller, driver, encoder, brake, and transformer available

Specifications

| Greensky Power Right Angle Gear AC Motor | |

| Motor type | Induction motor, brake motor, torque motor, speed adjustable motor, reversible motor |

| Frame size | 80mm, 90mm, 104mm |

| Motor Output speed | 1250rpm – 1500rpm |

| Gearbox Speed Ratio | 1:3 – 1: 100 |

| Output power | 80mm: 25W, 30W

90mm: 40W, 60W, 90W, 120W 104mm: 120W, 140W, 200W, 250W, 370W |

| Output shaft | 12mm ~ 50mm; round shaft, D-cut shaft, key-way shaft, hollow shaft |

| Voltage | 110v, 220v, 230v, 380v |

| Frequency | 50Hz, 60Hz |

Note:

If this model is not what you want, please freely tell us about your requirements. We will provide you with a suitable motor solution and price soon.

FAQ

1 Q: What’s your MOQ for the motor?

A: 1unit is ok for sample testing

2 Q: What about your warranty for your motor?

A: One year.

3 Q: Do you provide OEM service with customer logo?

A: Yes, we could do OEM orders, but we mainly focus on our own brand.

4 Q: How about your payment terms?

A: TT, western union, and PayPal. 100% payment in advance for orders less than $5,000. 30% deposit and balance before delivery for orders over $5,000.

5 Q: How about your packing?

A: Carton, Plywood case. If you need more, we can pack all goods in pallets.

6 Q: What information should be given, if I buy motors from you?

A: Rated power, gearbox ratio, input speed, mounting position. More details, better!

7 Q: How do you deliver the motors?

A: We will compare and choose the most suitable ways of delivery by sea, air or express courier.

We hope you will enjoy cooperating with us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | Single-Phase or Three-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there any emerging trends in brake motor technology, such as digital control?

Yes, there are emerging trends in brake motor technology that are shaping the future of this field. One such trend is the adoption of digital control systems, which offer several advantages over traditional control methods. These advancements in digital control are revolutionizing brake motor technology and unlocking new possibilities for improved performance, efficiency, and integration within industrial processes. Here’s a detailed explanation of the emerging trends in brake motor technology, including the shift towards digital control:

- Digital Control Systems: Digital control systems are becoming increasingly prevalent in brake motor technology. These systems utilize advanced microprocessors, sensors, and software algorithms to provide precise control, monitoring, and diagnostics. Digital control enables enhanced motor performance, optimized energy efficiency, and improved operational flexibility. It allows for seamless integration with other digital systems, such as programmable logic controllers (PLCs) or industrial automation networks, facilitating intelligent and interconnected manufacturing processes.

- Intelligent Motor Control: The integration of digital control systems with brake motors enables intelligent motor control capabilities. These systems use sensor feedback and real-time data analysis to dynamically adjust motor parameters, such as speed, torque, and braking force, based on the changing operating conditions. Intelligent motor control optimizes motor performance, minimizes energy consumption, and enhances overall system efficiency. It also enables predictive maintenance by continuously monitoring motor health and providing early warnings for potential faults or failures.

- Network Connectivity and Industry 4.0: Brake motors are increasingly designed to be part of interconnected networks in line with the principles of Industry 4.0. With digital control systems, brake motors can be connected to industrial networks, enabling real-time data exchange, remote monitoring, and control. This connectivity facilitates centralized monitoring and management of multiple brake motors, improves system coordination, and enables predictive analytics for proactive decision-making. It also allows for seamless integration with other smart devices and systems, paving the way for advanced automation and optimization in manufacturing processes.

- Condition Monitoring and Predictive Maintenance: Digital control systems in brake motors enable advanced condition monitoring and predictive maintenance capabilities. Sensors integrated into the motor can collect data on parameters such as temperature, vibration, and load conditions. This data is processed and analyzed in real-time, allowing for early detection of potential issues or performance deviations. By implementing predictive maintenance strategies, manufacturers can schedule maintenance activities more efficiently, reduce unplanned downtime, and optimize the lifespan and reliability of brake motors.

- Energy Efficiency Optimization: Digital control systems provide enhanced opportunities for optimizing energy efficiency in brake motors. These systems can intelligently adjust motor parameters based on load demand, operating conditions, and energy consumption patterns. Advanced algorithms and control techniques optimize the motor’s energy usage, reducing power wastage and maximizing overall energy efficiency. Digital control also enables integration with energy management systems, allowing for better monitoring and control of energy consumption across the entire manufacturing process.

- Data Analytics and Machine Learning: The integration of digital control systems with brake motors opens up possibilities for leveraging data analytics and machine learning techniques. By collecting and analyzing large volumes of motor performance data, manufacturers can gain valuable insights into process optimization, fault detection, and performance trends. Machine learning algorithms can be applied to identify patterns, predict motor behavior, and optimize control strategies. This data-driven approach enhances decision-making, improves productivity, and enables continuous improvement in manufacturing processes.

In summary, emerging trends in brake motor technology include the adoption of digital control systems, intelligent motor control, network connectivity, condition monitoring, predictive maintenance, energy efficiency optimization, and data analytics. These trends are driving innovation in brake motor technology, improving performance, efficiency, and integration within manufacturing processes. As digital control becomes more prevalent, brake motors are poised to play a vital role in the era of smart manufacturing and industrial automation.

Can you provide examples of machinery or equipment that frequently use brake motors?

In various industrial and manufacturing applications, brake motors are commonly used in a wide range of machinery and equipment. These motors provide braking functionality and enhance the safety and control of rotating machinery. Here are some examples of machinery and equipment that frequently utilize brake motors:

- Conveyor Systems: Brake motors are extensively used in conveyor systems, where they control the movement and stopping of conveyor belts. They ensure smooth and controlled starting, stopping, and positioning of material handling conveyors in industries such as logistics, warehousing, and manufacturing.

- Hoists and Cranes: Brake motors are employed in hoists and cranes to provide reliable load holding and controlled lifting operations. They ensure secure stopping and prevent unintended movement of loads during lifting, lowering, or suspension of heavy objects in construction sites, ports, manufacturing facilities, and other settings.

- Elevators and Lifts: Brake motors are an integral part of elevator and lift systems. They facilitate controlled starting, stopping, and leveling of elevators, ensuring passenger safety and smooth operation in commercial buildings, residential complexes, and other structures.

- Metalworking Machinery: Brake motors are commonly used in metalworking machinery such as lathes, milling machines, and drilling machines. They enable precise control and stopping of rotating spindles, ensuring safe machining operations and preventing accidents caused by uncontrolled rotation.

- Printing and Packaging Machinery: Brake motors are found in printing presses, packaging machines, and labeling equipment. They provide controlled stopping and precise positioning of printing cylinders, rollers, or packaging components, ensuring accurate printing, packaging, and labeling processes.

- Textile Machinery: In textile manufacturing, brake motors are used in various machinery, including spinning machines, looms, and winding machines. They enable controlled stopping and tension control of yarns, threads, or fabrics, enhancing safety and quality in textile production.

- Machine Tools: Brake motors are widely employed in machine tools such as grinders, saws, and machining centers. They enable controlled stopping and tool positioning, ensuring precise machining operations and minimizing the risk of tool breakage or workpiece damage.

- Material Handling Equipment: Brake motors are utilized in material handling equipment such as forklifts, pallet trucks, and automated guided vehicles (AGVs). They provide controlled stopping and holding capabilities, enhancing the safety and stability of load transport and movement within warehouses, distribution centers, and manufacturing facilities.

- Winches and Winders: Brake motors are commonly used in winches and winders for applications such as cable pulling, wire winding, or spooling operations. They ensure controlled stopping, load holding, and precise tension control, contributing to safe and efficient winching or winding processes.

- Industrial Fans and Blowers: Brake motors are employed in industrial fans and blowers used for ventilation, cooling, or air circulation purposes. They provide controlled stopping and prevent the fan or blower from freewheeling when power is turned off, ensuring safe operation and avoiding potential hazards.

These examples represent just a selection of the machinery and equipment where brake motors are frequently utilized. Brake motors are versatile components that enhance safety, control, and performance in numerous industrial applications, ensuring reliable stopping, load holding, and motion control in rotating machinery.

How do brake motors ensure controlled and rapid stopping of rotating equipment?

Brake motors are designed to ensure controlled and rapid stopping of rotating equipment by employing specific braking mechanisms. These mechanisms are integrated into the motor to provide efficient and precise stopping capabilities. Here’s a detailed explanation of how brake motors achieve controlled and rapid stopping:

1. Electromagnetic Brakes: Many brake motors utilize electromagnetic brakes as the primary braking mechanism. These brakes consist of an electromagnetic coil and a brake disc or plate. When the power to the motor is cut off or the motor is de-energized, the electromagnetic coil generates a magnetic field that attracts the brake disc or plate, creating friction and halting the rotation of the motor shaft. The strength of the magnetic field and the design of the brake determine the stopping torque and speed, allowing for controlled and rapid stopping of the rotating equipment.

2. Spring-Loaded Brakes: Some brake motors employ spring-loaded brakes. These brakes consist of a spring that applies pressure on the brake disc or plate to create friction and stop the rotation. When the power is cut off or the motor is de-energized, the spring is released, pressing the brake disc against a stationary surface and generating braking force. The spring-loaded mechanism ensures quick engagement of the brake, resulting in rapid stopping of the rotating equipment.

3. Dynamic Braking: Dynamic braking is another technique used in brake motors to achieve controlled stopping. It involves converting the kinetic energy of the rotating equipment into electrical energy, which is dissipated as heat through a resistor or regenerative braking system. When the power is cut off or the motor is de-energized, the motor acts as a generator, and the electrical energy generated by the rotating equipment is converted into heat through the braking system. This dissipation of energy slows down and stops the rotation of the equipment in a controlled manner.

4. Control Systems: Brake motors are often integrated with control systems that enable precise control over the braking process. These control systems allow for adjustable braking torque, response time, and braking profiles, depending on the specific requirements of the application. By adjusting these parameters, operators can achieve the desired level of control and stopping performance, ensuring both safety and operational efficiency.

5. Coordinated Motor and Brake Design: Brake motors are designed with careful consideration of the motor and brake compatibility. The motor’s characteristics, such as torque, speed, and power rating, are matched with the braking system’s capabilities to ensure optimal performance. This coordinated design ensures that the brake can effectively stop the motor within the desired time frame and with the necessary braking force, achieving controlled and rapid stopping of the rotating equipment.

Overall, brake motors employ electromagnetic brakes, spring-loaded brakes, dynamic braking, and control systems to achieve controlled and rapid stopping of rotating equipment. These braking mechanisms, combined with coordinated motor and brake design, enable precise control over the stopping process, ensuring the safety of operators, protecting equipment from damage, and maintaining operational efficiency.

editor by CX 2024-05-16

China factory 12V 24V 48V 90V DC Right Angle Nmrv Orthogonal Worm Gearbox Reduction Gear Reducer Motor vacuum pump connector

Product Description

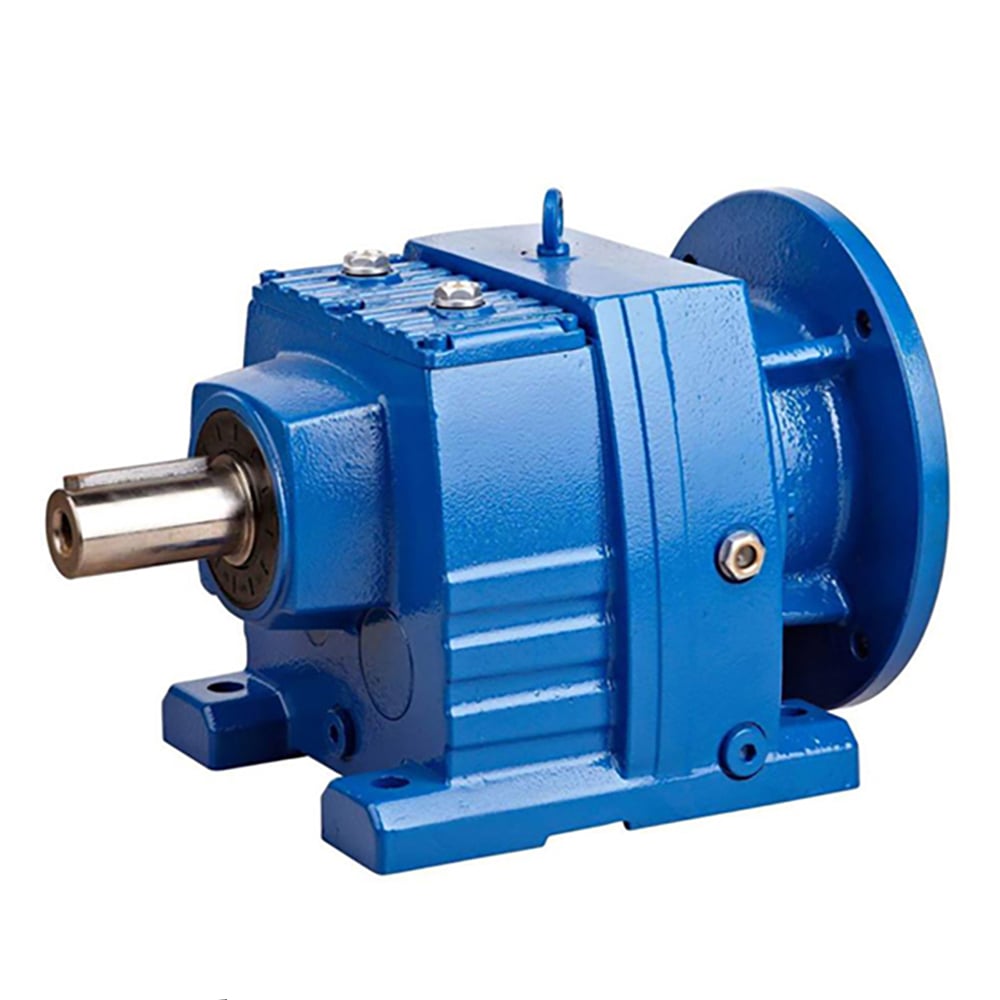

12V 24V 48V 90V DC Right Angle Nmrv Orthogonal Worm Gearbox Reduction Gear Reducer BLDC Motor

Features

1) Dimensions: 60*60mm, 70*60mm, 80*80mm, 90*80mm, 90*90mm, 104*90mm

2) Power: 15W 20W 30W 60W 80W 100W 120W 180W 200W 400W

3) Voltage: 12V 24V 48V 90V 310V

4) Rated speed: 2000rpm, 3000rpm

5) Reduction ratio: 3~ 200K

Product Photos

Product Description

| Motor type | Brush type / Brushless type / Stepper type | ||

| Frame size | 16mm ~ 130mm… can be customized | ||

| Running speed | Motor 1500-4000 rpm, Gear Ratio 1/3 ~ 1/3000 | ||

| Output power | 3W ~2200W… can be customized | ||

| Output shaft | round shaft, D-cut shaft, key-way shaft, hollow shaft… | ||

| Voltage type | 12V / 24V / 36V / 48V / 90V / 110V /220V… can be customized | ||

| Accessories | Internal driver / External driver / Connector / Brake / Encoder… | ||

| Gearbox type | Parallel shaft | ||

| Right angle hollow worm shaft | Right angle bevel hollow shaft | Flat type hollow shaft | |

| Right angle CHINAMFG worm shaft | Right angle bevel CHINAMFG shaft | Flat type CHINAMFG shaft | |

| Planetary center shaft | |||

Advantages

Certifications

FAQ

Q: Can you make the gear motor with customization?

A: Yes, we can customize per your request, like power, voltage, speed, shaft size, wires, connectors, IP grade, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What’s your lead time?

A: Standard products need 5-30 days, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, we can provide technical support if you

need.

Q: How to ship to us?

A: It is available by air, by sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with a different currency, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools |

|---|---|

| Operating Speed: | Constant Speed Adjust Speed High Speed Low Speed |

| Excitation Mode: | Excited |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Blue or Silver

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do brake motors ensure smooth and controlled movement in equipment?

Brake motors play a crucial role in ensuring smooth and controlled movement in equipment by providing reliable braking functionality. They work in coordination with the motor and other control systems to achieve precise control over the motion of the equipment. Here’s a detailed explanation of how brake motors ensure smooth and controlled movement in equipment:

- Braking Capability: Brake motors are specifically designed to provide effective braking capability. When the power to the motor is cut off or when a braking signal is applied, the brake system engages, generating frictional forces that slow down and bring the equipment to a controlled stop. The brake torque generated by the motor helps prevent coasting or unintended movement, ensuring smooth and controlled deceleration.

- Quick Response Time: Brake motors are engineered to have a quick response time, meaning that the brake engages rapidly once the control signal is applied. This quick response time allows for prompt and precise control over the movement of the equipment. By minimizing the delay between the initiation of the braking action and the actual engagement of the brake, brake motors contribute to smooth and controlled movement.

- Adjustable Brake Torque: Brake motors often offer the ability to adjust the brake torque to suit the specific requirements of the equipment and application. The brake torque can be tailored to the load characteristics and operating conditions to achieve optimal braking performance. By adjusting the brake torque, brake motors ensure that the equipment decelerates smoothly and consistently, avoiding abrupt stops or jerky movements.

- Brake Release Mechanisms: In addition to providing braking action, brake motors incorporate mechanisms to release the brake when the equipment needs to resume motion. These release mechanisms can be controlled manually or automatically, depending on the application. The controlled release of the brake ensures that the equipment starts moving smoothly and gradually, allowing for controlled acceleration.

- Integration with Control Systems: Brake motors are integrated into the overall control systems of the equipment to achieve coordinated and synchronized movement. They work in conjunction with motor control devices, such as variable frequency drives (VFDs) or servo systems, to precisely control the speed, acceleration, and deceleration of the equipment. By seamlessly integrating with the control systems, brake motors contribute to the smooth and controlled movement of the equipment.

- Compliance with Safety Standards: Brake motors are designed and manufactured in compliance with safety standards and regulations. They undergo rigorous testing and quality control measures to ensure reliable and consistent braking performance. By adhering to safety standards, brake motors help prevent sudden or uncontrolled movements that could pose a safety risk and ensure the equipment operates within acceptable limits.

By providing effective braking capability, quick response time, adjustable brake torque, release mechanisms, integration with control systems, and compliance with safety standards, brake motors ensure smooth and controlled movement in equipment. They enable precise control over the deceleration, stopping, and starting of the equipment, enhancing operational efficiency, safety, and overall performance.

How does a brake motor enhance safety in industrial and manufacturing settings?

In industrial and manufacturing settings, brake motors play a crucial role in enhancing safety by providing reliable braking and control mechanisms. These motors are specifically designed to address safety concerns and mitigate potential risks associated with rotating machinery and equipment. Here’s a detailed explanation of how brake motors enhance safety in industrial and manufacturing settings:

1. Controlled Stopping: Brake motors offer controlled stopping capabilities, allowing for precise and predictable deceleration of rotating machinery. This controlled stopping helps prevent abrupt stops or sudden changes in motion, reducing the risk of accidents, equipment damage, and injury to personnel. By providing smooth and controlled stopping, brake motors enhance safety during machine shutdowns, emergency stops, or power loss situations.

2. Emergency Stop Functionality: Brake motors often incorporate emergency stop functionality as a safety feature. In case of an emergency or hazardous situation, operators can activate the emergency stop function to immediately halt the motor and associated machinery. This rapid and reliable stopping capability helps prevent accidents, injuries, and damage to equipment, providing an essential safety measure in industrial environments.

3. Load Holding Capability: Brake motors have the ability to hold loads in position when the motor is not actively rotating. This load holding capability is particularly important for applications where the load needs to be securely held in place, such as vertical lifting mechanisms or inclined conveyors. By preventing unintended movement or drift of the load, brake motors ensure safe operation and minimize the risk of uncontrolled motion that could lead to accidents or damage.

4. Overload Protection: Brake motors often incorporate overload protection mechanisms to safeguard against excessive loads. These protection features can include thermal overload protection, current limiters, or torque limiters. By detecting and responding to overload conditions, brake motors help prevent motor overheating, component failure, and potential hazards caused by overburdened machinery. This protection enhances the safety of personnel and prevents damage to equipment.

5. Failsafe Braking: Brake motors are designed with failsafe braking systems that ensure reliable braking even in the event of power loss or motor failure. These systems can use spring-loaded brakes or electromagnetic brakes that engage automatically when power is cut off or when a fault is detected. Failsafe braking prevents uncontrolled motion and maintains the position of rotating machinery, reducing the risk of accidents, injury, or damage during power interruptions or motor failures.

6. Integration with Safety Systems: Brake motors can be integrated into safety systems and control architectures to enhance overall safety in industrial settings. They can be connected to safety relays, programmable logic controllers (PLCs), or safety-rated drives to enable advanced safety functionalities such as safe torque off (STO) or safe braking control. This integration ensures that the brake motor operates in compliance with safety standards and facilitates coordinated safety measures across the machinery or production line.

7. Compliance with Safety Standards: Brake motors are designed and manufactured in compliance with industry-specific safety standards and regulations. These standards, such as ISO standards or Machinery Directive requirements, define the safety criteria and performance expectations for rotating machinery. By using brake motors that meet these safety standards, industrial and manufacturing settings can ensure a higher level of safety, regulatory compliance, and risk mitigation.

8. Operator Safety: Brake motors also contribute to operator safety by reducing the risk of unintended movement or hazardous conditions. The controlled stopping and load holding capabilities of brake motors minimize the likelihood of unexpected machine behavior that could endanger operators. Additionally, the incorporation of safety features like emergency stop buttons or remote control options provides operators with convenient means to stop or control the machinery from a safe distance, reducing their exposure to potential hazards.

By providing controlled stopping, emergency stop functionality, load holding capability, overload protection, failsafe braking, integration with safety systems, compliance with safety standards, and operator safety enhancements, brake motors significantly enhance safety in industrial and manufacturing settings. These motors play a critical role in preventing accidents, injuries, and equipment damage, contributing to a safer working environment and ensuring the well-being of personnel.

What industries and applications commonly use brake motors?

Brake motors find wide-ranging applications across various industries that require controlled stopping, load holding, and precise positioning. Here’s a detailed overview of the industries and applications commonly using brake motors:

1. Material Handling: Brake motors are extensively used in material handling equipment such as cranes, hoists, winches, and conveyors. These applications require precise control over the movement of heavy loads, and brake motors provide efficient stopping and holding capabilities, ensuring safe and controlled material handling operations.

2. Elevators and Lifts: The vertical movement of elevators and lifts demands reliable braking systems to hold the load in position during power outages or when not actively driving the movement. Brake motors are employed in elevator systems to ensure passenger safety and prevent unintended movement or freefall of the elevator car.

3. Machine Tools: Brake motors are used in machine tools such as lathes, milling machines, drilling machines, and grinders. These applications often require precise positioning and rapid stopping of rotating spindles or cutting tools. Brake motors provide the necessary control and safety measures for efficient machining operations.

4. Conveyor Systems: Conveyor systems in industries like manufacturing, logistics, and warehouses utilize brake motors to achieve accurate control over the movement of goods. Brake motors enable smooth acceleration, controlled deceleration, and precise stopping of conveyor belts, ensuring proper material flow and minimizing the risk of collisions or product damage.

5. Crushers and Crushers: In industries such as mining, construction, and aggregates, brake motors are commonly used in crushers and crushers. These machines require rapid and controlled stopping to prevent damage caused by excessive vibration or unbalanced loads. Brake motors provide the necessary braking force to halt the rotation of crusher components quickly.

6. Robotics and Automation: Brake motors play a vital role in robotics and automation systems that require precise movement control and positioning. They are employed in robotic arms, automated assembly lines, and pick-and-place systems to achieve accurate and repeatable movements, ensuring seamless operation and high productivity.

7. Printing and Packaging: Brake motors are utilized in printing presses, packaging machines, and labeling equipment. These applications require precise control over the positioning of materials, accurate registration, and consistent stopping during printing or packaging processes. Brake motors ensure reliable performance and enhance the quality of printed and packaged products.

8. Textile Machinery: Brake motors are commonly found in textile machinery such as spinning machines, looms, and textile printing equipment. These applications demand precise control over yarn tension, fabric movement, and position holding. Brake motors offer the necessary braking force and control for smooth textile manufacturing processes.

9. Food Processing: Brake motors are employed in food processing equipment, including mixers, slicers, extruders, and dough handling machines. These applications require precise control over mixing, slicing, and shaping processes, as well as controlled stopping to ensure operator safety and prevent product wastage.

These are just a few examples, and brake motors are utilized in numerous other industries and applications where controlled stopping, load holding, and precise positioning are essential. The versatility and reliability of brake motors make them a preferred choice in various industrial sectors, contributing to enhanced safety, productivity, and operational control.

editor by CX 2024-03-29

China Custom 12 24 Volt Dc Worm Planetary Bldc Gearbox Motor 12V 24V 750 Watt Geared Reducer Forklift AGV Robot Brushless DC Motor motor brushes

Guarantee: 1 12 months

Design Variety: Brushless DC Equipment Motor

Usage: Admirer, AGV/Industrial Robot/Forklift/Computerized machine/Wise Appliances/Packing Equipment

Type: Brushless Motor

Torque: .23N.m-264N.M

Design: Long term Magnet

Commutation: Brushless

Safeguard Function: Entirely Enclosed

Speed(RPM): RPM/Personalized

Constant Current(A): .2A-245A

Performance: IE 2

Motor kind: Brushless DC Gear Motor

Direction of Rotation: CW/CCW

Voltage(V): 12V, 24V, 36V, 48V, 310V

Power: 20W-15KW,Custom

Gearbox variety: Worm gearbox, Planetary Gearbox, Normal Gearbox

Custom: Electricity, Voltage, Velocity, Shaft, Motor Size, Motor Lead, Brake

Reduction ratio: 1:3-1:350

Bulk shipping time: fifteen-20 days

Sample supply day: 2-fifteen times

MOQ: 1 pcs

Packaging Information: According to the dimension of the motor for secure packing.Standard packing:1pcs with 1 interior carton and 1 outdoors carton

Port: Xihu (West Lake) Dis.

Function: A. Substantial electricity range from 20W to 15KW B. Dia: 42mm-180mmC. Effortless for pace & course adjustmentD. Prosperous inventory and quickly delivery time in ten working daysE. Strong balance for driver/controllerF. Life span previously mentioned continuous 10000 hoursG. IP65 protection rank is offered for us H. Above 90% enery effectiveness motor is available I. 3D file is accessible if clients neededJ. Everlasting magnet brushless dc motor K.Substantial-performance and stable matching driver and controller Specification Kindly remind: As different consumers might need diverse motor parameter for fitting your tools. If below motor can’t suit your want, make sure you kindly ship inquiry to us with details for rated electrical power or torque,rated speed, Scorching sale Aluminum NMRV collection Worm Equipment Gearbox worm reduction gearbox nema stepper motor 150cc reverse gearbox and rated voltage for our new dimensions drawing generating for you. Click Here to make contact with me. Thanks a good deal! Major Merchandise Firm Profile DMKE motor is a specialised motor firm established in Y2009 by Haibing Jian,who boats 18 several years of encounter in the motor and controller business. Our firm located in Xihu (West Lake) Dis.,HangZhou,China.Our principal merchandise are brushless dc motor, brushless controller, dc servo motor and controller, planetary gear motors, worm gear motors, brush dc motor and AC motor. They are widely utilised in AGV, RGV, robots, barrier gate, lifting equipment, cleaning machines, health-related equipment, cafe equipment, packing machinery, amusement recreation machines, Farm put into action equipment cultivator rotary tiller tractor pushed 3 level PTO agricultural rotavator cultivator cars, industrial products and so on.With a plant spot of 4000 square meters, we have the independent layout and growth capabilities and sturdy technological drive,with an yearly output of far more than 1 million units. We can acknowledge OEM motor and controller based on customers’ need. Our Advantages FAQ

| Q1: What sort motors you can offer? |

| A1: For now, we largely offer Brushless DC Motor, DC Servo Motor, Generate Dheel, Servo Electrical Cylinder, Gearbox, Motor Controller, with diameter variety from sixteen to 220mm, and power variety from 5W to 20KW. |

| Q2: Are you motors reversible? |

| A2: Sure, nearly all dc and ac motor are reversible. We have specialized men and women who can teach how to get the perform by diverse wire link. |

| Q3: Is it achievable for you to build new motors if we supply the tooling cost? |

| A3: Of course. Please kindly share the thorough needs like efficiency, dimension, annual quantity, target cost and many others. Then we’ll make our analysis. Welcome to click listed here to send out your needs. |

| This fall: What is your after-sales companies? |

| A4: A) Totally free maintenance inside 12 months ensure, lifetime advisor. B) Skilled remedies in set up and routine maintenance.Welcome to click on right here contact me for specific items. |

The Basics of a Gear Motor

The basic mechanism behind the gear motor is the principle of conservation of angular momentum. The smaller the gear, the more RPM it covers and the larger the gear, the more torque it produces. The ratio of angular velocity of two gears is called the gear ratio. Moreover, the same principle applies to multiple gears. This means that the direction of rotation of each adjacent gear is always the opposite of the one it is attached to.

Induction worm gear motor

If you’re looking for an electric motor that can deliver high torque, an Induction worm gear motor might be the right choice. This type of motor utilizes a worm gear attached to the motor to rotate a main gear. Because this type of motor is more efficient than other types of motors, it can be used in applications requiring massive reduction ratios, as it is able to provide more torque at a lower speed.

The worm gear motor is designed with a spiral shaft that is set into splines in another gear. The speed at which the worm gear rotates is dependent on the torque produced by the main gear. Induction worm gear motors are best suited for use in low-voltage applications such as electric cars, renewable energy systems, and industrial equipment. They come with a wide range of power-supply options, including twelve-volt, 24-volt, and 36-volt AC power supplies.

These types of motors can be used in many industrial settings, including elevators, airport equipment, food packaging facilities, and more. They also produce less noise than other types of motors, which makes them a popular choice for manufacturers with limited space. The efficiency of worm gearmotors makes them an excellent choice for applications where noise is an issue. Induction worm gear motors can be compact and extremely high-torque.

While the Induction worm gear motor is most widely used in industrial applications, there are other kinds of gearmotors available. Some types are more efficient than others, and some are more expensive than others. For your application, choosing the correct motor and gearbox combination is crucial to achieving the desired result. You’ll find that the Induction worm gear motor is an excellent choice for many applications. The benefits of an Induction worm gear motor can’t be overstated.

The DC gear motor is an excellent choice for high-end industrial applications. This type of gearmotor is smaller and lighter than a standard AC motor and can deliver up to 200 watts of torque. A gear ratio of three to two can be found in these motors, which makes them ideal for a wide range of applications. A high-quality DC gear motor is a great choice for many industrial applications, as they can be highly efficient and provide a high level of reliability.

Electric gear motors are a versatile and widely used type of electric motor. Nevertheless, there are some applications that don’t benefit from them, such as applications with high shaft speed and low torque. Applications such as fan motors, pump and scanning machines are examples of such high-speed and high-torque demands. The most important consideration when choosing a gearmotor is its efficiency. Choosing the right size will ensure the motor runs efficiently at peak efficiency and will last for years.

Parallel shaft helical gear motor

The FC series parallel shaft helical gearmotor is a compact, lightweight, and high-performance unit that utilizes a parallel shaft structure. Its compact design is complemented by high transmission efficiency and high carrying capacity. The motor’s material is 20CrMnTi alloy steel. The unit comes with either a flanged input or bolt-on feet for installation. Its low noise and compact design make it an ideal choice for a variety of applications.

The helical gears are usually arranged in two rows of one another. Each row contains one or more rows of teeth. The parallel row has the teeth in a helical pattern, while the helical rows are lined up parallelly. In addition to this, the cross helical gears have a point contact design and do not overlap. They can be either parallel or crossed. The helical gear motors can have any number of helical pairs, each with a different pitch circle diameter.

The benefits of the Parallel Shaft Helical Gearbox include high temperature and pressure handling. It is produced by skilled professionals using cutting-edge technology, and is widely recognized for its high performance. It is available in a range of technical specifications and is custom-made to suit individual requirements. These gearboxes are durable and low-noise and feature high reliability. You can expect to save up to 40% of your energy by using them.

The parallel shaft helical gear motors are designed to reduce the speed of a rotating part. The nodular cast iron housing helps make the unit robust in difficult environments, while the precision-machined gears provide quiet, vibration-free operation. These motors are available in double reduction, triple reduction, and quadruple reduction. The capacity ranges from 0.12 kW to 45 kW. You can choose from a wide variety of capacities, depending on the size of your gearing needs.

The SEW-EURODRIVE parallel shaft helical gearmotor is a convenient solution for space-constrained applications. The machine’s modular design allows for easy mounting and a wide range of ambient temperatures. They are ideal for a variety of mechanical applications, including conveyors, augers, and more. If you want a small footprint, the SEW-EURODRIVE parallel shaft helical gear motor is the best solution for you.

The parallel shaft helical gears are advantageous for both high and low speed applications. Parallel helical gears are also suitable for low speed and low duty applications. A good example of a cross-helix gear is the oil pump of an internal combustion engine. Both types of helical gears are highly reliable and offer vibration-free operation. They are more costly than conventional gear motors, but offer more durability and efficiency.

Helical gear unit

This helical gear unit is designed to operate under a variety of demanding conditions and can be used in a wide range of applications. Designed for long life and high torque density, this gear unit is available in a variety of torques and gear ratios. Its design and construction make it compatible with a wide range of critical mechanical systems. Common applications include conveyors, material handling, steel mills, and paper mills.

Designed for high-performance applications, the Heidrive helical gear unit provides superior performance and value. Its innovative design allows it to function well under a wide range of operating conditions and is highly resistant to damage. These gear motors can be easily combined with a helical gear unit. Their combined power output is 100 Nm, and they have a high efficiency of up to 90%. For more information about the helical gear motor, contact a Heidrive representative.

A helical gear unit can be classified by its reference section in the standard plane or the turning plane. Its center gap is the same as that of a spur gear, and its number of teeth is the same. In addition to this, the helical gear has a low axial thrust, which is another important characteristic. The helical gear unit is more efficient at transferring torque than a spur gear, and it is quieter, too.

These units are designed to handle large loads. Whether you are using them for conveyors, augers, or for any other application that involves high-speed motion, a helical gear unit will deliver maximum performance. A helical gear unit from Flender can handle 400,000 tasks with a high degree of reliability. Its high efficiency and high resistance to load ensures high plant availability. These gear motors are available in a variety of sizes, from single-speed to multi-speed.

PEC geared motors benefit from decades of design experience and high quality materials. They are robust, quiet, and offer excellent performance. They are available in multiple configurations and are dimensionally interchangeable with other major brands. The gear motors are manufactured as modular kits to minimize inventory. They can be fitted with additional components, such as backstops and fans. This makes it easy to customize your gear motors and save money while reducing costs.

Another type of helical gears is the double helical gear. The double helical gear unit has two helical faces with a gap between them. They are better for enclosed gear systems as they provide greater tooth overlap and smoother performance. Compared to double helical gears, they are smaller and more flexible than the Herringbone type. So, if you’re looking for a gear motor, a helical gear unit may be perfect for you.

in El Paso United States sales price shop near me near me shop factory supplier Nmrv +Nmrv Series 063-130 Worm Gear Reducer Combination Gearbox Best Quality in China manufacturer best Cost Custom Cheap wholesaler

we are self-assured to provide our consumers versatile and diversified solutions. With EPG brand name registered in more than 70 nations around the world like America , Europe , Japan and so on, it has companions between globe best enterprises, these kinds of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth. makes certain the steadiness and regularity of the key operate of factors. We commenced our business from 1995 and now we are the a single of the leaEPTmanufacturer of EPT EPT products. It focuses mostly on Keyless Locking Gadgets, Timing Belt EPTs, Roller Chains, EPT, Jaw Couplings, Gears and other components.

These items are made in conformity with the Global StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd and the stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds adopted in EPTized countries (DIN EPT BS JIS) with up to data gear, EPT EPT and best administration system for top quality manage. It boasts a group with wealthy knowledge in this business, focusing on EPT market. So the goods are of very good high quality with aggressive prices.

Our objective : Supplying initial-course items and service to our consumers and company partners.

in Malang Indonesia sales price shop near me near me shop factory supplier Square Flange Mounted Worm Gear Reducer for Servo Motor manufacturer best Cost Custom Cheap wholesaler

We are aiming to satisfy the needs of the customers around the planet.. We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the Usa, Canada, and so forth. Sophisticated thermo remedy products, these kinds of as community heat treatment method oven, multi-use thermo treatment method oven, and so forth. Merchandise INTRODUCTION:

Primary Attributes:

1) Manufactured of large quality EPT alloy, ligEPT weigEPT and non-rusting

two) Large output torque and large radiating effectiveness three) Sleek managing and low noise, can function EPT time in dreadful condition

4) Great-seeking physical appearance, tough provider lifestyle and modest quantity

five) Suited for omnibearing installation

Major Resources:

one)housing: aluminium alloy ADC12(dimension 571-090) die cast iron EPT200(measurement a hundred and ten-one hundred fifty)

two)Worm:20Cr, ZI Involute profile carbonize ampquencher warmth treatment method make EPT area hardness up to fifty six-62 HRC Following precision grinding, carburization layer’s thickness among .3-.5mm.

three)Worm Wheel:wearable stannum alloy CuSn10-one

Product PARAMETERS:

| Size | Specification | EPT ratio | |||||||||||||

| IEC | N | M | P | 7.five | ten | 15 | twenty | twenty five | thirty | forty | fifty | sixty | 80 | one hundred | |

| D | |||||||||||||||

| 30 | 63B5 | ninety five | 115 | 140 | 11 | eleven | 11 | 11 | 11 | 11 | eleven | 11 | |||

| 63B14 | sixty | 75 | 90 | ||||||||||||

| 56B5 | eighty | one hundred | 120 | 9 | nine | 9 | 9 | nine | nine | nine | 9 | nine | nine | ||

| 56B14 | 50 | sixty five | 80 | nine | 9 | 9 | nine | 9 | 9 | 9 | 9 | nine | nine | ||

| 40 | 71B5 | one hundred ten | a hundred thirty | a hundred and sixty | fourteen | fourteen | 14 | fourteen | 14 | fourteen | fourteen | 14 | |||

| 71B14 | 70 | 85 | 105 | ||||||||||||

| 63B5 | ninety five | a hundred and fifteen | a hundred and forty | eleven | eleven | 11 | 11 | eleven | eleven | 11 | eleven | 11 | 11 | 11 | |

| 63B14 | 60 | seventy five | ninety | ||||||||||||

| 56B5 | 80 | a hundred | one hundred twenty | nine | nine | nine | nine | ||||||||

| fifty | 80B5 | a hundred thirty | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | – | – | – |

| 80B14 | 80 | a hundred | one hundred twenty | ||||||||||||

| 71B5 | 110 | a hundred thirty | a hundred and sixty | 14 | 14 | fourteen | 14 | fourteen | fourteen | fourteen | fourteen | 14 | fourteen | – | |

| 71B14 | 70 | 85 | one hundred and five | ||||||||||||

| 63B5 | 95 | 115 | one hundred forty | – | – | – | – | – | – | – | eleven | 11 | eleven | eleven | |

| sixty three | 90B5 | a hundred thirty | 165 | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | – | – | – |

| 90B14 | 95 | 115 | a hundred and forty | ||||||||||||

| 80B5 | 130 | one hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | |

| 80B14 | eighty | one hundred | 120 | ||||||||||||

| 71B5 | one hundred ten | a hundred thirty | one hundred sixty | – | – | – | – | – | – | fourteen | 14 | 14 | fourteen | fourteen | |

| 71B14 | 70 | 85 | one zero five | ||||||||||||

| 75 | a hundred/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | – | – | – | – | – | – | – | – |

| a hundred/112B14 | one hundred ten | one hundred thirty | 160 | ||||||||||||

| 90B5 | a hundred thirty | 165 | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||||

| 90B14 | 95 | 115 | 140 | ||||||||||||

| 80B5 | 130 | one hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80B14 | 80 | a hundred | 120 | ||||||||||||

| 71B5 | one hundred ten | a hundred thirty | 160 | fourteen | fourteen | 14 | 14 | ||||||||

| ninety | one hundred/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | – | – | – | – | – |

| one hundred/112B14 | a hundred and ten | 130 | 160 | ||||||||||||

| 90B5 | one hundred thirty | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||

| 90B14 | ninety five | one hundred fifteen | 140 | ||||||||||||

| 80B5 | a hundred thirty | a hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | |||||||

| 80B14 | 80 | one hundred | 120 | ||||||||||||

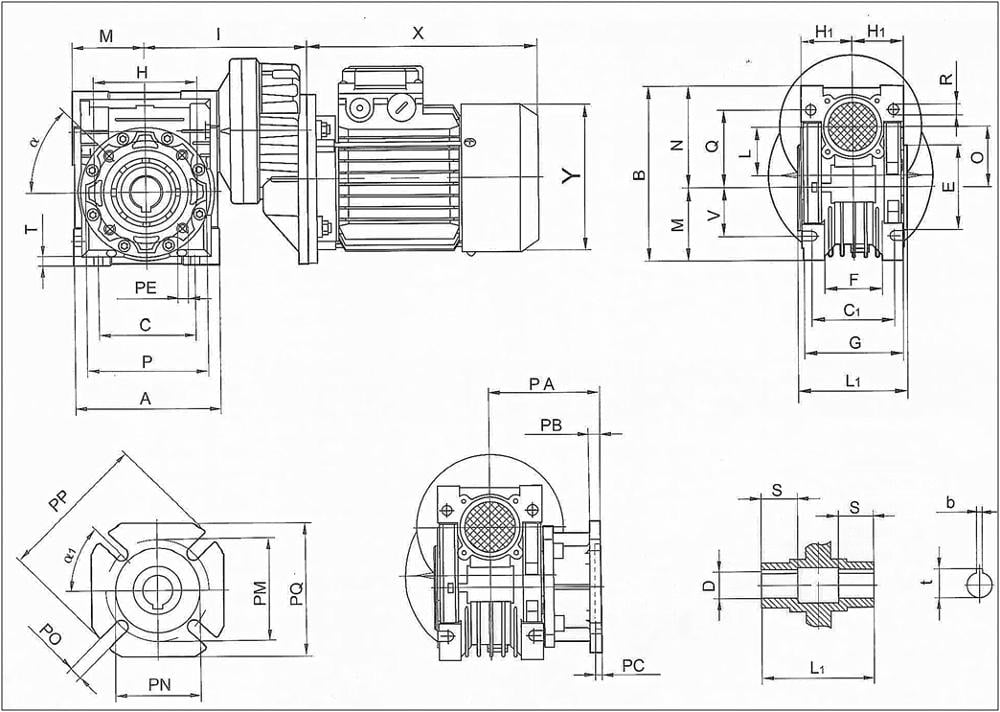

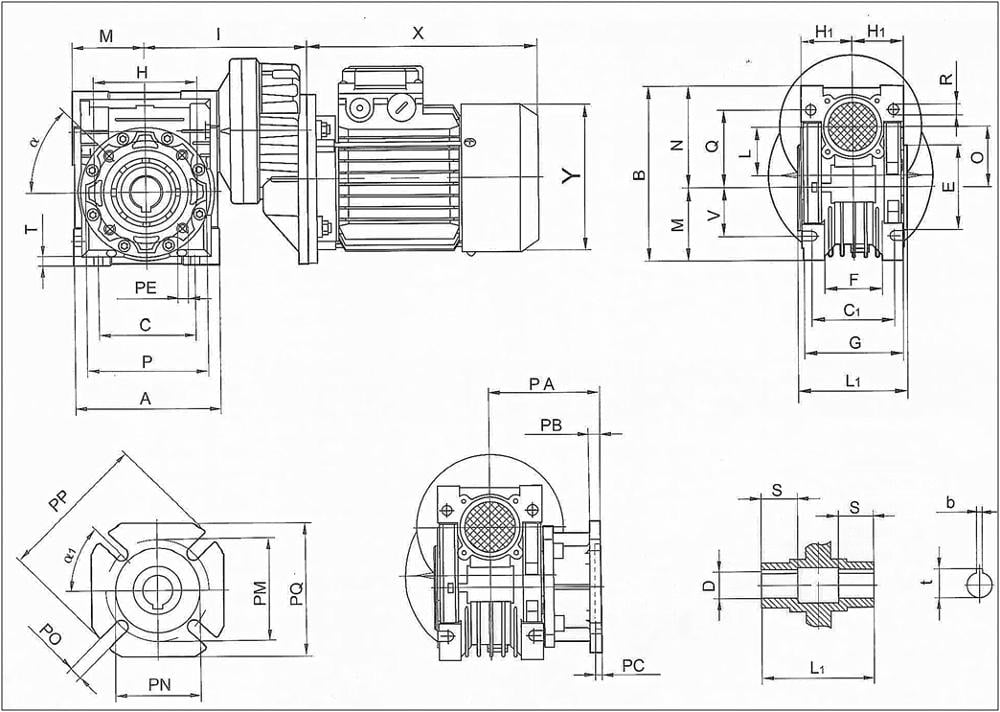

Solution Outline Dimensions:

Organization Quick INTRODUCTION:

We are a skilled EPT manufacturer found in EPTizhou, EPT province.

Our foremost products is entire selection of RV571-a hundred and fifty worm EPTs , also supplied hypoid helical EPT, Computer units, UDL Variators and AC EPTs.

EPT are commonly utilised for apps this sort of as: foodstuffs, EPT, EPT, chemical substances, pharmacy, plastics, paper-making, design EPTry, metallurgic EPT, environmental protection engineering, and all sorts of automated lines, and assembly lines.

With fast shipping, exceptional after-revenue services, EPT creating faXiHu (West Lake) Dis.Hu (West Lake) Dis.ty, our goods market effectively equally at home and overseas. We have exported our EPTs to SouthEPT Asia, EPTern Europe and the Middle EPT and so on.Our purpose is to deveXiHu (West Lake) Dis.Hu (West Lake) Dis. and innovate on the foundation of large good quality, and EPT a excellent popularity for EPTs.

WORKSHOP:

EXHIBITIONS:

FAQ:

one.Q:Can you make as per client drawing?

A: Indeed, we offer you customized service for buyers accordingly. We can use customer’s nameplate for EPTes.

2.Q:What is your conditions of payment ?

A: thirty% deposit prior to creation,harmony T/T prior to shipping and delivery.

3.Q:Are you a trading company or manufacturer?

A:We are a manufacurer with EPT equipment and experienced staff.

four.Q:What is your generation ability?

A:8000-9000 PCS/Thirty day period

4.Q:What is your MOQ?

A: 1 pcs

5.Q:Free of charge sample is available or not?

A:Yes, we can offer free sample if buyer concur to shell out for the courier EPT

six.Q:Do you have any certificate?

A:Sure, we have CE certification and SGS certification report.

Contact information:

Ms Lingel Pan

For any concerns just really feel totally free ton contact me. Many many thanks for your type consideration to our business!

in Seoul Republic of Korea sales price shop near me near me shop factory supplier Nmrv050 Worm Gear Reducer with B5 B14 Flange manufacturer best Cost Custom Cheap wholesaler

With many years’ experience in this line, we will be trustworthy by our benefits in competitive price, 1-time delivery, prompt response, on-hand engineering assist and very good following-income providers.Moreover, all our production methods are in compliance with ISO9001 requirements. Thanks to our sincerity in giving very best services to our clients, comprehending of your demands and overriding feeling of accountability towards filling purchasing requirements, Total use has been produced of all varieties of advanced tactics and technologies to attain excelsior manufacturing. Worm EPT EPT parameters

| Sort | Worm Equipment Speed EPT EPT |

| Model | NMRV30-a hundred and fifty |

| Ratio | five,7.5,ten,fifteen,20,25,30,forty,fifty,60,80,one hundred |

| Coloration | Blue / Silver or OEM hues |

| EPT | EPT-Casting iron-EPT200# / Aluminium |

| Worm Gear | KK alloy |

| Worm | 20CrMnTi with carburizing and quenching, area hardness is fifty eight-62HRC |

| Shaft | chromium metal-45# |

| EPT | Paper Carton,Plywood box / for each set(With foam board within) |

| EPT | Brand quotHRE quot, quotC ampU quot EPT |

| Seal | NAK or SKF |

| Input EPT | .06-15KW |

| Usages | In EPT EPT: Meals things,Ceramics,chemical, aswell as EPT, printing, dyeing,woodworking, EPT and plastics.. |

| IEC Flange | 56B5,63B5,80B5,90B5,100B5,112B5,132B5…. |

| Lubricant | BODA Artificial oil(RV030-ninety),G-N460W Mineral oil(RV110-a hundred and fifty) |

Programs (extensively utilised in) :

Ceramic Market

Glass Sector

Foodstuff Industry

EPTlurgy Business

Beer amp Consume Market

EPT and dyeing Industry

Textile Industry

Warehouse Logoistics Sector

EPT operating EPTry

environmental security gear Sector

Leather-based Sector

Pharmacy Market

Developing EPT Industry

1.Our Services

one.one.We supply twelve months Warranty.

1.two. We have hundreds of EPT EPTs. From Input EPT .06KW to 200KW, Ratio 1.3-289.seventy four, Output velocity -1095rpm and Output torque 1.4-62800Nm. They can meet your all distinct requirements for diverse EPT.

one.3. We supply E-catalog or Paper catalog,so you can choose the product easily in accordance to your requirements

1.four.You are welcome to check out our manufacturing unit to examine our products,we can aid you to ebook the hotel or ticket

2.Organization Details

two.one.Our Organization:

The Predecessor for ZheJiang EPT Drive CO.,Ltd (at first referred to as HangEPT XiHu (West Lake) Dis.ngguang EPT EPTry CO.,Ltd) State-owned navy mould EPTrpriese which estabEPTd in 1965.

EPT is situated in HangEPT,EPT and the factory covers an spot of about 25000 sq. meters.

Manufacturing Ability:more than 50 percent a million sets of speed EPT for every yr.

2.two.Our People:

The firm has a powerful technological force. It has far more than four hundred workers at present, incXiHu (West Lake) Dis.Hu (West Lake) Dis. more than forty engineering experts and ten professionals and senior engineers enEPTing EPT allowances of the Condition Council.

2.three. Our Certificates:

Handed quot ISO 9001 Global EPT Program Certification quot, quotInternational EPT Credit AAA Ceritifacte quot , quot Swiss SGS Certification quot, Iconic Manufacturer in EPT EPT Market quot, quotFamous Model of ZheJiang Province quot, quotNon-general public Scientific and Technological EPTrprise in ZheJiang Province quot, quotNational Higher and EPT-tech EPTrprise quot, quotTOP fifty in EPT Gear Market quot quot2011 HangEPT Engineering and Technological R ampD CEPTr quot and so on.

three. FAQ

Q:Are you a trading firm or company?

A: The predecessor of HangEPT XG-EPT EPTry Co., Ltd is Point out-owned XiHu (West Lake) Dis.ngguanggong Mold Factory, a point out-owned armed forces EPT EPTrprise estabEPTd in 1965. It completed reform in 2002. Since reform, EPT has deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ed rapidly. It took the lead in passing ISO9001 Worldwide EPT Technique Certificate and Worldwide EPT Credit rating AAA Certificate in 2004, and Swiss SGS Certificate in 2009. It has won these kinds of titles as quotIconic Manufacturer in EPT EPT Industry quot, quotFamous Brand name of ZheJiang Province quot, quotNon-public Scientific and Technological EPTrprise in ZheJiang Province quot, quotNational High and EPT-tech EPTrprise quot, and quotTope 50 in EPT Gear Business quot successively

Q:Exactly where do you foundation?

A: We are in HangEPT,ZheJiang ,EPT. We have two factories,EPT manufacturing unit is in XiHu (West Lake) Dis.hu (West Lake) Dis. district,HangEPT,EPT and the aged one particular is in CHangEPT District,HangEPT,EPT.

Q:What varieties of EPT can you generate for us?

A:Major products of our company: JWB-X collection mechanical continually variable EPT, RV sequence worm EPT EPT, B/JXJ cycloidal pin EPT speed EPT, NCJ series EPT EPT, and R, S, K, and F series helical-tooth EPT, a lot more than one particular hundred versions and countless numbers of specifications.

Q:What are the software of the EPT?

A:EPT are extensively used in ceramic, EPT, meals, metallurgy, beer amp consume, printing and dyeing, textile, petrochemical engineering, warehouse EPT, wooden-doing work EPT, environmental protection products, printing and EPT, pharmacy, and leather-based. EPT are bought in some nations and areas, this sort of as Europe, The united states, and SouthEPT Asia, and it possesses dozens of distributors and right after-sale provider brokers.

Q:What is the content you use?

A: EPT situation ( For the RV series worm EPT)

B: Solid iron(For the RV collection worm EPT, Dimension one hundred ten-one hundred fifty, For the NCJ amp F/R/S/K series helical EPT EPT)

Our manufacturing facility (ZheJiang EPT Generate Co., Ltd.) is a large and popular 6S stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT manufacturing facility with around 380 staff considering that 1965 . We export to South Asia, SouthEPT Asia, Africa, Middle EPT, South America, North The us, Europe…etc. We provide EPT to SIEMENS,ABB,SACMI,BUHLER…and so on. Sincerely hope to build a acquire-earn company romantic relationship with you.

Anticipating to speak about more details with you !

Greatest Wishes

Any inquiry pls contact:

Nicola EPTng (Export income)

Internet site:

in Tanger Morocco sales price shop near me near me shop factory supplier Nmrv040 Series Worm Gear Box Nmrv Cast Iron Worm Gear Reducer Shaft of Reducer NEMA Gear Reducer Stepper Motor Gearbox manufacturer best Cost Custom Cheap wholesaler

It has established stable cooperation with a lot of effectively acknowledged universities and institutes in china these kinds of as, Zhejiang University, Jilin College, Complex committee of national chain push normal, Institute of countrywide chain generate, Zhejiang application engineering material institute, Huhan content defense institute and it cooperated to discovered China Very first Automobile chain institute with Nationwide chain travel institute. If you are fascinated in any of our products or would like to talk about a possible buy, you should really feel totally free to get in touch with us. With numerous years’ knowledge in this line, we will be trusted by our benefits in aggressive value, a single-time shipping and delivery, prompt reaction, on-hand engineering support and great after-sales companies.Furthermore, all our generation techniques are in compliance with ISO9001 specifications.

Minimal EPT NMRV series worm EPT utilized marine EPT for sale,cheap worm EPT box charges for textile EPTs

Merchandise Description

NMRV Employed Marine EPT

1. Mad of substantial-good quality EPT alloy,ligEPT weigEPT and non-rusting

two. Huge output torque

3. Smooth in working and lower in sound,can operate EPT time in dreadful circumstances.

four. Substantial in radiating efficiency.

five. Excellent-searching in appearance,tough in support daily life and modest in quantity.

six. Ideal for omnibearing installation.

| Product No.: | NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

| Ratio: | 5,7.five,10,fifteen,twenty,25,thirty,40,50,60,eighty,100 |

| Colour: | Blue(Ral5571)/Silver Grey (RAL9006) Or On Customer Ask for |

| EPT: | EPT: Measurement 25-110 Is EPT Alloy, Measurement one hundred ten-150 Is Cast-Iron |

| Worm Wheel: ZCuSn10Pb1 | |

| Worm:20Cr | |

| Pinion:Tin Bronze | |

| Output Shaft: Metal-45# | |

| Usages: | EPT EPT: Meals Stuff, Ceramics, Chemical, EPT, Dyeing,EPT functioning, Glass. |

| IEC Flange: | IEC StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Flange Or On Buyer Ask for |

Business Data

EPT control

EPT

EPT Particulars: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd carton/Pallet/StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd wood situation

Shipping Information : 15-30 operating daEPTupon payment

Our Certifications

Connected Solution

EPT Planetary EPT

| EPT Planetary EPT | Robot RV EPT pace EPT |

| Custom made created Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT | UDL Sequence Variator |

| PYZ Series Helical Tooth Shaft Mounted EPT | 8000 Collection Cycloidal EPT |

| SLT Sequence Spiral EPTl EPT | SLSWL Collection Worm Screw Jack |

| SLP Series Planetary EPT | SLH/SLB Collection Large EPT EPT |

| NMRV Sequence Worm EPT | BKM Collection Helical-hypoid EPT |

| SLRC Sequence Helical EPT | SLSMR Collection Shaft Mounted EPT |

| SLXG Series Shaft Mounted EPT | X/B Collection Cycloidal EPT |

| SLR/SEPT/SLK/SLS Collection Helical EPT | AC/DC EPT |

FAQ

one.Payment Phrase: TT, L/C

two.Supply time: about 30 daEPTfrom EPT payment.

three.We accept custom-made items as for each your EPT requirement.

four.XiHu (West Lake) Dis.hu (West Lake) Dis.traces for the Assortment:Usually we can pick one EPT which is appropriate for you with some informations from you,this sort of as ratio/motor velocity/mounting dimension/ out torque and so forth.

5.If the minimum orEPTamount is in extra of $ten thousand, there are preferential.

Q1: What data must I explain to you to confirm the product?

A:Product/Dimension, EPT Ratio, Shaft instructions amp OrEPTquantity.

Q2: What can i do if I don’t know which one particular EPT?

A:Dont be concerned, Send out as significantly information as you can, our group will assist you discover the rigEPT a single you are looking for.

Q3: What is your merchandise guarantee interval?

A:We supply 1 12 months warranty since the vessel departure day still left EPT.

This autumn: Are you buying and selling organization or maker ?

A: We are manufacturing unit.

Q5: How EPT is your shipping and delivery time?

A: EPTly it is five-ten daEPTif the products are in stock. or it is 15-twenty daEPTif the items are not in stock, it is in accordance to amount.

Q6: Do you offer samples ? is it free of charge or further ?

A: Indeed, we could offer you the sample for totally free demand but do not spend the EPT of freight.

Q7: What is your phrases of payment ?

A: Payment lt=1000USD, one hundred% EPT. Payment gt=1000USD, thirty% T/T EPT ,harmony before shippment.

If you have an additional query, pls come to feel totally free to speak to us as below:

Contact Us

in Villavicencio Colombia sales price shop near me near me shop factory supplier RV Worm Combination Gear Speed Gearbox Reducer manufacturer best Cost Custom Cheap wholesaler

Our goods are used in many fields. Hangzhou EPG Co.,Ltd. , was founded in November, 1997. With its 5 wholly owned subsidiaries. In the meantime, our merchandise are produced according to higher good quality requirements, and complying with the international superior regular requirements.

RV Worm Blend Equipment Pace EPT EPT

NMRV 571-a hundred and fifty worm EPT box with flange and electric motor

NMRV NMRV EPT Stage Arrangement Reduction Gear Box

RV Sequence Worm EPT

worm velocity EPT

nmrv worm EPT motor

RV Collection

IncXiHu (West Lake) Dis.Hu (West Lake) Dis. RV / NMRV / NRV.

Main Characteristic of RV Sequence Worm EPT

RV collection worm EPT EPT is a new-generation solution deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ed by EPT on the foundation of perfecting WJ collection merchandise with a compromise of EPT EPT each at home and overseas.

one. Large-quality EPT alloy, ligEPT in weigEPT and non-rusting.

two. Big in output torque.

three. Sleek operating and low sound,tough in dreadful conditions.

four. Higher radiation effectiveness.

5. Great-looking appearance, tough in support life and tiny quantity.

six. Appropriate for omnibearing installation.

Major EPTs of RV Collection Worm EPT

1. EPT: die-forged EPT alloy(frame measurement: 571 to 090), solid iron(body dimension: 110 to a hundred and fifty).

two. Worm: 20Crm, carbonization quencher warmth treatment makes the floor hardness of worm EPTs up to fifty six-62 HRX, retain carbonization layer’s thickness in between .3 and .5mm following specific grinding.

3. Worm Wheel: wearable stannum bronze alloy.

| Velocity RATIO | 7.five~100 |

| OUTPUT TORQUE | lt1050NM |

| IN EPT | .09-11KW |

| MOUNTING Type | FOOT-MOUNTED FLANGE-MOUNTED |

| When working, wonderful load ability, steady working, reduced noise with large performance. | |||||||

| Gear Box’s Use Field | |||||||

| one | EPTlurgy | 11 | Agitator | ||||

| 2 | Mine | twelve | Rotary weeder | ||||

| three | EPT | 13 | EPTlurgy | ||||

| 4 | Vitality | fourteen | Compressor | ||||

| 5 | EPT | 15 | EPT business | ||||

| 6 | Water Conserbancy | 16 | Air Compressor | ||||

| seven | EPTcco | seventeen | Crusher | ||||

| eight | Medical | 18 | EPTs | ||||

| 9 | EPT | 19 | Electronics | ||||

| 10 | Chemical market | twenty | Textile indutry | ||||

| … | … | ||||||

| EPT | .06kw | .09kw | .12kw | .18kw | .25kw | .37kw | .55kw |

| .75kw | 1.1kw | 1.5kw | two.2kw | 3kw | 4kw | five.5kw | |

| seven.5kw | 11kw | 15kw | |||||

| Torque | 2.6N.m-3000N.m | ||||||

| Ratio | 7.five-100, the double EPT is far more | ||||||

| Shade | Blue, Silver or as customers’ need to have | ||||||

| EPT | Iron or Aluminium | ||||||

| EPT | Carton with Plywood Scenario or as clients’ prerequisite | ||||||

| Sort | RV571 | RV030 | RV040 | RV050 | RV063 | RV075 | RV090 |

| Excess weight | .7kg | one.3kg | two.3kg | three.5kg | six.2kg | 9kg | 13kg |

| Sort | RV110 | RV130 | RV150 | ||||

| Weight | 35kg | 60kg | 84kg | ||||

| Mounting Techniques | Foot Set up | Flange Installation | |||||

| For different mortor or double input/output shafts can be outfitted | |||||||

Product image:

Composition:

Certification:

EPT amp Shipping and delivery:

Our business :

EPT reg was founded in 1982, which has more than 36 many years in R amp D and manufacturing of EPTes, EPTs, shaft, motor and spare components.

We can provide the correct answer for uncountable purposes. Our goods are broadly used in the ranges of metallurgical, steel, mining, pulp and paper, suXiHu (West Lake) Dis.Hu (West Lake) Dis. and alcohol industry and a variety of other varieties of EPTs with a powerful existence in the worldwide market place.

EPT reg has grow to be a dependable supplier, able to provide high quality EPTes.With 36 many years expertise, we guarantee you the utmost reliability and protection for equally product and providers.

Customer browsing:

FAQ:

one.Q:What varieties of EPT can you produce for us?

A:Primary merchandise of our organization: UDL series velocity variator,RV collection worm EPT EPT, ATA sequence shaft mounted EPT, X,B collection EPT EPT,

P collection planetary EPT and R, S, K, and F series helical-tooth EPT, far more

than a single hundred types and thousands of specs

two.Q:Can you make as for each personalized drawing?

A: Sure, we supply custom-made service for consumers.

3.Q:What is your conditions of payment ?

A: 30% Progress payment by T/T following signing the agreement.70% before delivery

4.Q:What is your MOQ?

A: 1 Set

Get in touch with:

Tel: -371-53667898

Fax: -371-86571652

Cell: -1873657180

Deal with: No.1394, Hanghai Highway, HangEPT, EPT

Zip Code: 450016

Welcome you contace me if you are intrigued in our item.

Our staff will assist any need to have you migEPT have.

China manufacturer & factory supplier for china in Coimbatore India manufacturer factory of NRV worm gear reducer series With high quality best price & service

Manufacturer & distributor of roller & wire rope conclude chains. Kinds of chains contain alloy, substantial tensile transport, large take a look at & proof coil chains. Programs consist of log chains, cargo lashings, pipe line handing, tailgates, guard rails & change chains.With several years’ experience in these traces, we have been distinguished from other suppliers in China by our positive aspects in aggressive pricing, on-time shipping and delivery, prompt responses, on-hand engineering assist and good right after-sales solutions.

Overview

Fast Particulars

- Relevant Industries:

-

Production Plant

- Software:

-

Mining

- Weight:

-

.4-45kg

- Rated Power:

-

.12-200 KW

- Colour:

-

Customer Request

- Substance:

-

Solid Iron

- Certification:

-

ISO9001

- Mount Place:

-

Foot Mounted. Flange Mounted

- Delivery:

-

Categorical

- MOQ:

-

1pcs

EPG Machinery is situated in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou international airport.

- Good quality:

-

Substantial Precision

Packaging & Shipping and delivery

-

Guide Time

: -

Amount(Bags) After the PTO has begun to energy the attachment, steadily improve the throttle till you reach the functioning speed. The normal running RPM (revolutions for every moment) for a tractor mounted PTO is 540 RPM, although there are tractor types that rev higher. Usually refer to your certain tractor product for recommendations prior to 1st-time use.

1 – 1 two – 10 >10 Est. Time(days) 5 thirteen To be negotiated

Online Customization

Merchandise Description

NMRV gearbox

NMRV reducer is a new sort of reducer, also acknowledged as RV reducer. “NMRV” is a common expression, it refers to the aluminum reducer, the globe has been employed to aluminum reducer referred to as “NMRV reducer”. The major factors are oil seal, oil plug, worm equipment box, ball bearing, output shaft, worm wheel, worm, output shaft, motor disk (flange), output shaft include, hexagon socket head screw, double spherical key, gasket, and so on. BHADE reducer, one particular of NMRV series, has solitary flange enter, flange output or double shaft output.

- Attributes

The weight of NMRV reducer is relatively gentle, the shell is manufactured of aluminum alloy, which has the advantages of gentle fat, exceptional toughness, beautiful appearance, substantial warmth dissipation efficiency, lengthy provider lifestyle, noiseless movement and other positive aspects, practical and simple link with the motor. NMRV reducer is a type of functional transmission tools, and its appearance style and its integration are much more in line with public desire than other varieties of reducer. Though the RV reducer manufactured of aluminum alloy only emerged in 2007, its application field and reputation are even a lot more superior than other kinds of reducer. It is a variety of reducer with large practicability and a fusion of innovative technologies at house and overseas. NMRV reducer is really convenient to connect with normal motor, stepless gearbox and flanged electromagnetic clutch brake set. No coupling is needed. Can be ideal for all – spherical set up, and the output torque is also comparatively massive, function relatively clean and so on.

Specifics Images

Business

OUR Company

We are a manufacturer in ZJ Province, China. Our firm owns the capacity of manufacturing, processing, planning and R&D. We welcome your pay a visit to.

We manage the merchandise of power transmission, our strains primarily go over sequence merchandise in speed reducers, gearboxes , connected electricial motors and other electricity transmission add-ons. Primarily based on the flexible functions, our products can be utilized in a lot of fields: devices of waste drinking water treatment method, dredgers, chemical sector, cranes, steel operating mills, conveyors, paper industry, cement sector, cableways and so on.With the excellent high quality Dressing grinding wheels leaves a microscopic surface “thread” which, beneath the right problems, can transfer to the seal journal and create a leak path.and sensible value , our merchandise get pleasure from a good reputation from consumers and the peers all more than the world.

Our charges are often aggressive. If the buyer can place a big get, we certainly will enable low cost.

Certifications

Packing & Supply

FAQ

Q1: Are you a investing firm or a manufacturer ?

A: We are a producer in ZJ Province, China. Our business owns

the capability of production, processing, creating and R&D. We welcome your go to.

Q2: How we decide on versions and technical specs?

A: In accordance to the particular information of the requires from the part of enquiry,

we will advise the products’ versions upon synthesizing the factors of

discipline of products use, electricity, torque arm and ratio…

Q3: How is your value? Can you offer you any price cut?

A: Our costs are usually competitive. If the client can place a huge get,

we certainly will enable low cost.

This autumn: How extended should I wait around for the opinions following I send the enquiry?

A: We will reply as quickly as possible, 12 hours at most.

Q5: What is your item warranty period of time?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes becoming utilized?

A: Our gearboxes are broadly utilized to metallurgical gear, mining

equipment, automation equipment, foods equipment, packaging tools,

tobacco gear and so on.

Best China manufacturer & factory RV in Baghdad Iraq series worm reducer gearboxes worm gear box precision With high quality best price

If you want any info or samples, you should speak to us and you will have our before long reply.

Overview

Swift Details

- Relevant Industries:

-

Production Plant, Machinery Restore Stores, farms

- Gearing Arrangement:

-

worm

- Output Torque:

-

a thousand

- Enter Velocity:

-

1400

- Output Speed:

-

240

- Area of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Rated Electricity:

-

2.five

Our products are marketing effectively in Chinese marketplaces and some items marketed in international marketplaces are properly acquired by Chinese and international clientele at property and overseas.

- Product Quantity:

-

NMRV

Provide Capability

- Offer Capability:

- one hundred thousand Piece/Parts per Month

Packaging & Delivery

- Packaging Specifics

- picket

- Port

- shanghai

On the web Customization

RV collection worm gearbox/ RV worm gWorm Gears A worm gear program is made up of a worm and worm wheel positioned as a cross axis and is the most compact kind of equipment method. Due to the compact layout, worm equipment reducers are ready to be put in relatively tiny areas and supply large-ratio velocity reduction. Worm gears are identified to operate efficiently and quietly, as prolonged as they are properly mounted and lubricated.earbox/ worm gearbox

Comprehensive Solution Description

Box Worm Reducer in Auminum Alloy is with Eourpean technoA PTO shaft transfers the electrical power from the tractor to the PTO run attachment. This allows the tractor to electricity a assortment of tractor implements which includes flail mowers, wooden chippers, rotary tillers, excavators, and far more.logy.Its stucture , define and set up dimension as well as functionality are same with that of European items, they are interchangeable ,and the materials and machining procedure are innovative internationally.The item is highlighted by:

one. Low sounds and temperature increase.

two. High bearing capability,easy working and prolonged support life.

three. Compact structure,tiny volume, gentle weight, beartiful form and easy to put in.

4. Can run repeatedly beneath server environment, and has a very good reliability.

This type of reducer can be widely used for pace-reducing driving for various devices in petrochemical market, tabacco equipment, grain, oil ,foods and forage machinery,gentle market, textile ,surge refining , pharmacy, leather-based business, environmental and traffic and transportation,etc.,they are the pace reducers that are used the most extensively at present in numerous creation strains in European international locations.

….