Product Description

1,Integrate motor, battery and control module all in 1 wheel.

2,Replace your front wheel,convert any bike into an smart e-bike.

| Product Name | Lvbu Wheel(Electric bike kit) |

| Cable Location | shaft center right |

| Motor | 250W Gear Motor(Maximum Power 500W) |

| Rim | Aluminum Alloy Double-Wall with Tyre |

| Wheel Size | 16″ 20″ 24″ 26″ 27.5″ 29″ 700C |

| Max Speed | 35km/h (settable in the APP to meet different regulation) |

| Controller | WePower intelligent Assist System |

| Module | Bluetooth 4.0 Cortex-M3 6-axis Gyroscope |

| Brake Type | V Brake / Disc Brake |

| Open Size | Front Fork 80/100mm |

| Battery capacity | 36V 8.7AH |

| Charger | 36V 2A |

| Charging time | About 2hrs |

| Assist range | 90km |

| Display&Throttle | Bluetooth Display with thumb throttle(Optional) |

| Weight(Kg) | 9Kg |

Company Introduction

ZheJiang CHINAMFG technology co,.Ltd is established in 2014,Our company is a professional manufacturer engaged in the research, development, production, sale and service of electric bicycle kit. We are located in HangZhou and have convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as South America. We also welcome OEM and ODM orders.Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Conversion Kits |

|---|---|

| Wheel Size: | 16"-29"(700c) |

| Open Size: | Front:100mm |

| Samples: |

US$ 350/Piece

1 Piece(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do brake motors handle variations in brake torque and response time?

Brake motors are designed to handle variations in brake torque and response time to ensure reliable and efficient braking performance. These variations can arise due to different operating conditions, load characteristics, or specific application requirements. Here’s a detailed explanation of how brake motors handle variations in brake torque and response time:

- Brake Design and Construction: The design and construction of brake systems in brake motors play a crucial role in handling variations in brake torque and response time. Brake systems typically consist of brake pads or shoes that press against a brake disc or drum to generate frictional forces and provide braking action. The materials used for the brake components, such as brake linings, can be selected or designed to offer a wide range of torque capacities and response characteristics. By choosing the appropriate materials and optimizing the brake system design, brake motors can accommodate variations in torque requirements and response times.

- Brake Control Mechanisms: Brake motors employ different control mechanisms to manage brake torque and response time. These mechanisms can be mechanical, electrical, or a combination of both. Mechanical control mechanisms often utilize springs or levers to apply and release the brake, while electrical control mechanisms rely on electromagnets or solenoids to engage or disengage the brake. The control mechanisms can be adjusted or configured to modulate the brake torque and response time based on the specific needs of the application.

- Brake Torque Adjustments: Brake motors may offer provisions for adjusting the brake torque to accommodate variations in load requirements. This can be achieved through the selection of different brake linings or by adjusting the spring tension or magnetic force within the brake system. By modifying the brake torque, brake motors can provide the necessary braking force to meet the demands of different operating conditions or load characteristics.

- Response Time Optimization: Brake motors can be engineered to optimize the response time of the braking system. The response time refers to the time it takes for the brake to engage or disengage once the control signal is applied. Several factors can influence the response time, including the design of the control mechanism, the characteristics of the brake linings, and the braking system’s overall dynamics. By fine-tuning these factors, brake motors can achieve faster or slower response times as required by the application, ensuring effective and timely braking action.

- Electronic Control Systems: In modern brake motors, electronic control systems are often employed to enhance the flexibility and precision of brake torque and response time adjustments. These systems utilize sensors, feedback mechanisms, and advanced control algorithms to monitor and regulate the brake performance. Electronic control allows for real-time adjustments and precise control of the brake torque and response time, making brake motors more adaptable to variations in operating conditions and load requirements.

By combining appropriate brake design and construction, control mechanisms, torque adjustments, response time optimization, and electronic control systems, brake motors can effectively handle variations in brake torque and response time. This enables them to provide reliable and efficient braking performance across a wide range of operating conditions, load characteristics, and application requirements.

How do manufacturers ensure the quality and reliability of brake motors?

Manufacturers employ various processes and measures to ensure the quality and reliability of brake motors. These processes involve rigorous testing, adherence to industry standards, quality control procedures, and continuous improvement initiatives. Here’s a detailed explanation of how manufacturers ensure the quality and reliability of brake motors:

- Design and Engineering: Manufacturers invest considerable effort in the design and engineering phase of brake motors. They employ experienced engineers and designers who follow industry best practices and utilize advanced design tools to develop motors with robust and reliable braking systems. Thorough analysis, simulations, and prototyping are conducted to optimize the motor’s performance, efficiency, and safety features.

- Material Selection: High-quality materials are chosen for the construction of brake motors. Manufacturers carefully select components such as motor windings, brake discs, brake pads, and housing materials to ensure durability, heat resistance, and optimal friction characteristics. The use of quality materials enhances the motor’s reliability and contributes to its long-term performance.

- Manufacturing Processes: Stringent manufacturing processes are implemented to ensure consistent quality and reliability. Manufacturers employ advanced machinery and automation techniques for precision assembly and production. Strict quality control measures are applied at each stage of manufacturing to detect and rectify any defects or deviations from specifications.

- Testing and Quality Assurance: Brake motors undergo comprehensive testing and quality assurance procedures before they are released to the market. These tests include performance testing, load testing, endurance testing, and environmental testing. Manufacturers verify that the motors meet or exceed industry standards and performance specifications. Additionally, they conduct safety tests to ensure compliance with applicable safety regulations and standards.

- Certifications and Compliance: Manufacturers seek certifications and compliance with relevant industry standards and regulations. This may include certifications such as ISO 9001 for quality management systems or certifications specific to the motor industry, such as IEC (International Electrotechnical Commission) standards. Compliance with these standards demonstrates the manufacturer’s commitment to producing high-quality and reliable brake motors.

- Quality Control and Inspection: Manufacturers implement robust quality control processes throughout the production cycle. This includes inspection of raw materials, in-process inspections during manufacturing, and final inspections before shipment. Quality control personnel conduct visual inspections, dimensional checks, and performance evaluations to ensure that each brake motor meets the specified quality criteria.

- Continuous Improvement: Manufacturers prioritize continuous improvement initiatives to enhance the quality and reliability of brake motors. They actively seek customer feedback, monitor field performance, and conduct post-production evaluations to identify areas for improvement. This feedback loop helps manufacturers refine their designs, manufacturing processes, and quality control procedures, leading to increased reliability and customer satisfaction.

- Customer Support and Warranty: Manufacturers provide comprehensive customer support and warranty programs for their brake motors. They offer technical assistance, troubleshooting guides, and maintenance recommendations to customers. Warranty coverage ensures that any manufacturing defects or malfunctions are addressed promptly, bolstering customer confidence in the quality and reliability of the brake motors.

By employing robust design and engineering processes, meticulous material selection, stringent manufacturing processes, comprehensive testing and quality assurance procedures, certifications and compliance with industry standards, rigorous quality control and inspection measures, continuous improvement initiatives, and dedicated customer support and warranty programs, manufacturers ensure the quality and reliability of brake motors. These measures contribute to the production of high-performance motors that meet the safety, durability, and performance requirements of industrial and manufacturing applications.

How do brake motors handle variations in load and stopping requirements?

Brake motors are designed to handle variations in load and stopping requirements by incorporating specific features and mechanisms that allow for flexibility and adaptability. These features enable brake motors to effectively respond to changes in load conditions and meet the diverse stopping requirements of different applications. Here’s a detailed explanation of how brake motors handle variations in load and stopping requirements:

1. Adjustable Braking Torque: Brake motors often have adjustable braking torque, allowing operators to modify the stopping force according to the specific load requirements. By adjusting the braking torque, brake motors can accommodate variations in load size, weight, and inertia. Higher braking torque can be set for heavier loads, while lower braking torque can be selected for lighter loads, ensuring optimal stopping performance and preventing excessive wear or damage to the braking system.

2. Controlled Response Time: Brake motors provide controlled response times, allowing for precise and efficient stopping according to the application requirements. The response time refers to the duration between the command to stop and the actual cessation of rotation. Brake motors can be designed with adjustable response times, enabling operators to set the desired stopping speed based on the load characteristics and safety considerations. This flexibility ensures that the braking action is appropriately matched to the load and stopping requirements.

3. Dynamic Braking: Dynamic braking is a feature found in some brake motors that helps handle variations in load and stopping requirements. When the motor is de-energized, dynamic braking converts the kinetic energy of the rotating load into electrical energy, which is dissipated as heat through a resistor or regenerative braking system. This braking mechanism allows brake motors to handle different load conditions and varying stopping requirements, dissipating excess energy and bringing the rotating equipment to a controlled stop.

4. Integrated Control Systems: Brake motors often come equipped with integrated control systems that allow for customized programming and adjustment of the braking parameters. These control systems enable operators to adapt the braking performance based on the load characteristics and stopping requirements. By adjusting parameters such as braking torque, response time, and braking profiles, brake motors can handle variations in load and achieve the desired stopping performance for different applications.

5. Monitoring and Feedback: Some brake motor systems incorporate monitoring and feedback mechanisms to provide real-time information about the load conditions and stopping performance. This feedback can include data on motor temperature, current consumption, or position feedback from encoders or sensors. By continuously monitoring these parameters, brake motors can dynamically adjust their braking action to accommodate variations in load and ensure optimal stopping performance.

6. Adaptable Brake Design: Brake motors are designed with consideration for load variations and stopping requirements. The brake design takes into account factors such as braking surface area, material composition, and cooling methods. These design features allow brake motors to handle different load conditions effectively and provide consistent and reliable stopping performance under varying circumstances.

By incorporating adjustable braking torque, controlled response time, dynamic braking, integrated control systems, monitoring and feedback mechanisms, and adaptable brake designs, brake motors can handle variations in load and stopping requirements. These features enhance the versatility and performance of brake motors, making them suitable for a wide range of applications across different industries.

editor by CX 2024-05-16

China OEM Universal CE Certified bldc hub electric with gearbox 220V brake dc motor vacuum pump brakes

Product Description

Product Description:

Gear Motor-Torque Table Allowance Torque Unit:Upside (N.m)/Belowside (kgf.cm)

•Gearhead and Intermediate gearhead are sold separately.

•Enter the reduction ratio into the blank() within the model name.

•The speed is calculated by dividing the motor’s synchronous speed by the reduction ratio. The actual speed is 2%~20% less than the displayed value, depending on the size of the load.

•To reduce the speed beyond the reduction ratio in the following table, attach an intermediate gearhead (reduction ratio: 10) between the reducer and motor. In that case, the permissible torque is 20N.m.

|

Type Motor/Gearhead |

Gear Ratio |

3 |

3.6 |

5 |

6 |

7.5 |

9 |

12.5 |

15 |

18 |

25 |

30 |

36 |

50 |

60 |

75 |

90 |

100 |

120 |

150 |

180 |

|

Speed r/min |

866 |

722 |

520 |

433 |

346 |

288 |

208 |

173 |

144 |

104 |

86 |

72 |

52 |

43 |

34 |

28 |

26 |

21 |

17 |

14 |

|

| Z5D120-24GU-M(5GU180KB) |

5GU()RC/ 5GU()RT |

0.87 |

1.04 |

1.45 |

1.74 |

2.41 |

5.44 |

4.02 |

4.82 |

5.78 |

8.03 |

9.64 |

10.4 |

14.5 |

17.4 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

20.0 |

|

8.87 |

10.6 |

14.8 |

17.7 |

24.6 |

55.5 |

41.0 |

48.2 |

59.0 |

81.9 |

98.3 |

106 |

148 |

177 |

200 |

200 |

200 |

200 |

200 |

200 |

Dimensions(Unit:mm):

Company Information

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you () /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Power Tools |

|---|---|

| Operating Speed: | Constant Speed |

| Structure and Working Principle: | Brushless |

| Certification: | ISO9001, CCC, CCC, CE, RoHS, UL |

| Commutation: | Brushless |

| Transport Package: | Cnt |

| Customization: |

Available

|

|

|---|

Can brake motors be used in conjunction with other motion control methods?

Yes, brake motors can be used in conjunction with other motion control methods to achieve precise and efficient control over mechanical systems. Brake motors provide braking functionality, while other motion control methods offer various means of controlling the speed, position, and acceleration of the system. Combining brake motors with other motion control methods allows for enhanced overall system performance and versatility. Here’s a detailed explanation of how brake motors can be used in conjunction with other motion control methods:

- Variable Frequency Drives (VFDs): Brake motors can be used in conjunction with VFDs, which are electronic devices that control the speed and torque of an electric motor. VFDs enable precise speed control, acceleration, and deceleration of the motor by adjusting the frequency and voltage supplied to the motor. By incorporating a brake motor with a VFD, the system benefits from both the braking capability of the motor and the advanced speed control provided by the VFD.

- Servo Systems: Servo systems are motion control systems that utilize servo motors and feedback mechanisms to achieve highly accurate control over position, velocity, and torque. In certain applications where rapid and precise positioning is required, brake motors can be used in conjunction with servo systems. The brake motor provides the braking function when the system needs to hold position or decelerate rapidly, while the servo system controls the dynamic motion and positioning tasks.

- Stepper Motor Control: Stepper motors are widely used in applications that require precise control over position and speed. Brake motors can be utilized alongside stepper motor control systems to provide braking functionality when the motor needs to hold position or prevent undesired movement. This combination allows for improved stability and control over the stepper motor system, especially in applications where holding torque and quick deceleration are important.

- Hydraulic or Pneumatic Systems: In some industrial applications, hydraulic or pneumatic systems are used for motion control. Brake motors can be integrated into these systems to provide additional braking capability when needed. For example, a brake motor can be employed to hold a specific position or provide emergency braking in a hydraulic or pneumatic actuator system, enhancing safety and control.

- Control Algorithms and Systems: Brake motors can also be utilized in conjunction with various control algorithms and systems to achieve specific motion control objectives. These control algorithms can include closed-loop feedback control, PID (Proportional-Integral-Derivative) control, or advanced motion control algorithms. By incorporating a brake motor into the system, the control algorithms can utilize the braking functionality to enhance overall system performance and stability.

The combination of brake motors with other motion control methods offers a wide range of possibilities for achieving precise, efficient, and safe control over mechanical systems. Whether it is in conjunction with VFDs, servo systems, stepper motor control, hydraulic or pneumatic systems, or specific control algorithms, brake motors can complement and enhance the functionality of other motion control methods. This integration allows for customized and optimized control solutions to meet the specific requirements of diverse applications.

What factors should be considered when selecting the right brake motor for a task?

When selecting the right brake motor for a task, several factors should be carefully considered to ensure optimal performance and compatibility with the specific application requirements. These factors help determine the suitability of the brake motor for the intended task and play a crucial role in achieving efficient and reliable operation. Here’s a detailed explanation of the key factors that should be considered when selecting a brake motor:

1. Load Characteristics: The characteristics of the load being driven by the brake motor are essential considerations. Factors such as load size, weight, and inertia influence the torque, power, and braking requirements of the motor. It is crucial to accurately assess the load characteristics to select a brake motor with the appropriate power rating, torque capacity, and braking capability to handle the specific load requirements effectively.

2. Stopping Requirements: The desired stopping performance of the brake motor is another critical factor to consider. Different applications may have specific stopping time, speed, or precision requirements. The brake motor should be selected based on its ability to meet these stopping requirements, such as adjustable braking torque, controlled response time, and stability during stopping. Understanding the desired stopping behavior is crucial for selecting a brake motor that can provide the necessary control and accuracy.

3. Environmental Conditions: The operating environment in which the brake motor will be installed plays a significant role in its selection. Factors such as temperature, humidity, dust, vibration, and corrosive substances can affect the performance and lifespan of the motor. It is essential to choose a brake motor that is designed to withstand the specific environmental conditions of the application, ensuring reliable and durable operation over time.

4. Mounting and Space Constraints: The available space and mounting requirements should be considered when selecting a brake motor. The physical dimensions and mounting options of the motor should align with the space constraints and mounting configuration of the application. It is crucial to ensure that the brake motor can be properly installed and integrated into the existing machinery or system without compromising the performance or safety of the overall setup.

5. Power Supply: The availability and characteristics of the power supply should be taken into account. The voltage, frequency, and power quality of the electrical supply should match the specifications of the brake motor. It is important to consider factors such as single-phase or three-phase power supply, voltage fluctuations, and compatibility with other electrical components to ensure proper operation and avoid electrical issues or motor damage.

6. Brake Type and Design: Different brake types, such as electromagnetic brakes or spring-loaded brakes, offer specific advantages and considerations. The choice of brake type should align with the requirements of the application, taking into account factors such as braking torque, response time, and reliability. The design features of the brake, such as braking surface area, cooling methods, and wear indicators, should also be evaluated to ensure efficient and long-lasting braking performance.

7. Regulatory and Safety Standards: Compliance with applicable regulatory and safety standards is crucial when selecting a brake motor. Depending on the industry and application, specific standards and certifications may be required. It is essential to choose a brake motor that meets the necessary standards and safety requirements to ensure the protection of personnel, equipment, and compliance with legal obligations.

8. Cost and Lifecycle Considerations: Finally, the cost-effectiveness and lifecycle considerations should be evaluated. This includes factors such as initial investment, maintenance requirements, expected lifespan, and availability of spare parts. It is important to strike a balance between upfront costs and long-term reliability, selecting a brake motor that offers a favorable cost-to-performance ratio and aligns with the expected lifecycle and maintenance budget.

Considering these factors when selecting a brake motor helps ensure that the chosen motor is well-suited for the intended task, provides reliable and efficient operation, and meets the specific requirements of the application. Proper evaluation and assessment of these factors contribute to the overall success and performance of the brake motor in its designated task.

Can you explain the primary purpose of a brake motor in machinery?

The primary purpose of a brake motor in machinery is to provide controlled stopping and holding of loads. A brake motor combines the functionality of an electric motor and a braking system into a single unit, offering convenience and efficiency in various industrial applications. Here’s a detailed explanation of the primary purpose of a brake motor in machinery:

1. Controlled Stopping: One of the main purposes of a brake motor is to achieve controlled and rapid stopping of machinery. When power is cut off or the motor is turned off, the braking mechanism in the brake motor engages, creating friction and halting the rotation of the motor shaft. This controlled stopping is crucial in applications where precise and quick stopping is required to ensure the safety of operators, prevent damage to equipment, or maintain product quality. Industries such as material handling, cranes, and conveyors rely on brake motors to achieve efficient and controlled stopping of loads.

2. Load Holding: Brake motors are also designed to hold loads in a stationary position when the motor is not actively rotating. The braking mechanism in the motor engages when the power is cut off, preventing any unintended movement of the load. Load holding is essential in applications where it is necessary to maintain the position of the machinery or prevent the load from sliding or falling. For instance, in vertical applications like elevators or lifts, brake motors hold the load in place when the motor is not actively driving the movement.

3. Safety and Emergency Situations: Brake motors play a critical role in ensuring safety and mitigating risks in machinery. In emergency situations or power failures, the braking system of a brake motor provides an immediate response, quickly stopping the rotation of the motor shaft and preventing any uncontrolled movement of the load. This rapid and controlled stopping enhances the safety of operators and protects both personnel and equipment from potential accidents or damage.

4. Precision and Positioning: Brake motors are utilized in applications that require precise positioning or accurate control of loads. The braking mechanism allows for fine-tuned control, enabling operators to position machinery or loads with high accuracy. Industries such as robotics, CNC machines, and assembly lines rely on brake motors to achieve precise movements, ensuring proper alignment, accuracy, and repeatability. The combination of motor power and braking functionality in a brake motor facilitates intricate and controlled operations.

Overall, the primary purpose of a brake motor in machinery is to provide controlled stopping, load holding, safety in emergency situations, and precise positioning. By integrating the motor and braking system into a single unit, brake motors streamline the operation and enhance the functionality of various industrial applications. Their reliable and efficient braking capabilities contribute to improved productivity, safety, and operational control in machinery and equipment.

editor by CX 2024-05-10

China Best Sales 10inch 38 Holes 215 Dropout Electric Motorcycle Spoke Hub Motor with Drum/Disc Brake Oil to Electricity Kit for Pakistan with Hot selling

Product Description

1.Company building

2.Product introduction

Used in scooter and motorcycle with high power

giving excellent balance capacity,comfortable,smooth and durable in use.

| working voltage | DC48V-DC72V |

| No load speed | 1000rpm Max |

| Rated power | 1500W Max |

| efficiency | >=90% |

| Maximum torque | 120Nm |

| Maximum speed | 45km/h-60km/h |

| Brake type | Hub/Disc brake |

| colour | Regular black, other colors can be customized |

| Rim | 10 inch Spoke Motor |

| Applicable models | Electric motorcycle |

3.Hub Motor picture

4.Production process

5.Gallery picture

6.Loading process

6.Our Service

1. OEM Manufacturing welcome: Product, Package,logo and brand.

2. Sample order :Free sampls but you need pay for freight.

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every 2 days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

7.FAQ

1. Q: Can I get samples before my formal order?

A: Yes, special sample services are available. And the sample cost can be relived once the formal order comes.

2. Q: How do you control the quality?

A: 1. Provide sample test report confirmation; 2. Seal sample confirmation. 3. Shoot production videos during the production process; 4. Send out test reports and test videos when the products are off-line; 5. Use foam cartons and woven bags for packaging, and the perfect packaging method ensures that the products are not damaged during transportation.

3. Q: Can I get a customize service?

A: Yes, ODM OEM services are available. (Appearance color, decal, power, etc. can be customized if the quantity can be above 50sets)

4. Q: What is the warranty time of your products?

A:The motor and controller are guaranteed for 18 months.

5. Q: How about payment terms and price terms?

A: Payment Terms: EXW,FOB,CNF/CFR,CIF,L/C, etc. Price Terms: Sample list 100%;Regular order 100% TT or 100% L/C or 30%TT,70%L/C.The specific payment method can be negotiated.

6. Q: What’s the approximate lead time?

A: After the advanced payment confirmed, normally 5 days for stock products,15 days for conventional models , and 30 days for special models.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Charge |

|---|---|

| Warranty: | 18 Months |

| Type: | Motor |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety precautions should be followed when working with brake motors?

Working with brake motors requires adherence to specific safety precautions to ensure the well-being of personnel and the proper functioning of the equipment. Brake motors involve electrical components and potentially hazardous mechanical operations, so it is essential to follow established safety guidelines. Here’s a detailed explanation of the safety precautions that should be followed when working with brake motors:

- Qualified Personnel: Only trained and qualified individuals should be allowed to work with brake motors. They should have a thorough understanding of electrical systems, motor operation, and safety procedures. Proper training ensures that personnel are familiar with the specific risks associated with brake motors and know how to handle them safely.

- Power Isolation: Before performing any maintenance or repair tasks on a brake motor, it is crucial to isolate the power supply to the motor. This can be achieved by disconnecting the power source and following lockout/tagout procedures to prevent accidental re-energization. Power isolation eliminates the risk of electric shock and allows safe access to the motor without the danger of unexpected startup.

- Personal Protective Equipment (PPE): When working with brake motors, appropriate personal protective equipment should be worn. This may include safety glasses, gloves, protective clothing, and hearing protection, depending on the specific hazards present. PPE helps safeguard against potential hazards such as flying debris, electrical shocks, and excessive noise, providing an additional layer of protection for personnel.

- Proper Ventilation: Adequate ventilation should be ensured when working with brake motors, especially in indoor environments. Ventilation helps dissipate heat generated by the motor and prevents the buildup of potentially harmful fumes or gases. Proper ventilation reduces the risk of overheating and improves air quality, creating a safer working environment.

- Safe Lifting and Handling: Brake motors can be heavy and require proper lifting and handling techniques to prevent injuries. When moving or installing a motor, personnel should use appropriate lifting equipment, such as cranes or hoists, and follow safe lifting practices. It is important to avoid overexertion, use proper body mechanics, and seek assistance when necessary to prevent strains or accidents.

- Protection Against Moving Parts: Brake motors may have rotating or moving parts that pose a risk of entanglement or crushing injuries. Guards and protective covers should be in place to prevent accidental contact with these hazardous areas. Personnel should never reach into or attempt to adjust the motor while it is in operation or without proper lockout/tagout procedures in place.

- Maintenance and Inspection: Regular maintenance and inspection of brake motors are essential for their safe and reliable operation. Maintenance tasks should only be performed by qualified personnel following manufacturer recommendations. Before conducting any maintenance or inspection, the motor should be properly isolated and de-energized. Visual inspections, lubrication, and component checks should be carried out according to the motor’s maintenance schedule to identify and address any potential issues before they escalate.

- Follow Manufacturer Guidelines: It is crucial to follow the manufacturer’s guidelines and recommendations when working with brake motors. This includes adhering to installation procedures, operating instructions, and maintenance practices specified by the manufacturer. Manufacturers provide specific safety instructions and precautions that are tailored to their equipment, ensuring safe and efficient operation when followed meticulously.

- Training and Awareness: Ongoing training and awareness programs should be implemented to keep personnel updated on safety practices and potential hazards associated with brake motors. This includes providing clear instructions, conducting safety meetings, and promoting a safety-conscious culture. Personnel should be encouraged to report any safety concerns or incidents to ensure continuous improvement of safety measures.

By following these safety precautions, personnel can mitigate risks and create a safer working environment when dealing with brake motors. Adhering to proper procedures, using appropriate PPE, ensuring power isolation, practicing safe lifting and handling, protecting against moving parts, conducting regular maintenance and inspections, and staying informed about manufacturer guidelines are all crucial steps in maintaining a safe and efficient work environment when working with brake motors.

What factors should be considered when selecting the right brake motor for a task?

When selecting the right brake motor for a task, several factors should be carefully considered to ensure optimal performance and compatibility with the specific application requirements. These factors help determine the suitability of the brake motor for the intended task and play a crucial role in achieving efficient and reliable operation. Here’s a detailed explanation of the key factors that should be considered when selecting a brake motor:

1. Load Characteristics: The characteristics of the load being driven by the brake motor are essential considerations. Factors such as load size, weight, and inertia influence the torque, power, and braking requirements of the motor. It is crucial to accurately assess the load characteristics to select a brake motor with the appropriate power rating, torque capacity, and braking capability to handle the specific load requirements effectively.

2. Stopping Requirements: The desired stopping performance of the brake motor is another critical factor to consider. Different applications may have specific stopping time, speed, or precision requirements. The brake motor should be selected based on its ability to meet these stopping requirements, such as adjustable braking torque, controlled response time, and stability during stopping. Understanding the desired stopping behavior is crucial for selecting a brake motor that can provide the necessary control and accuracy.

3. Environmental Conditions: The operating environment in which the brake motor will be installed plays a significant role in its selection. Factors such as temperature, humidity, dust, vibration, and corrosive substances can affect the performance and lifespan of the motor. It is essential to choose a brake motor that is designed to withstand the specific environmental conditions of the application, ensuring reliable and durable operation over time.

4. Mounting and Space Constraints: The available space and mounting requirements should be considered when selecting a brake motor. The physical dimensions and mounting options of the motor should align with the space constraints and mounting configuration of the application. It is crucial to ensure that the brake motor can be properly installed and integrated into the existing machinery or system without compromising the performance or safety of the overall setup.

5. Power Supply: The availability and characteristics of the power supply should be taken into account. The voltage, frequency, and power quality of the electrical supply should match the specifications of the brake motor. It is important to consider factors such as single-phase or three-phase power supply, voltage fluctuations, and compatibility with other electrical components to ensure proper operation and avoid electrical issues or motor damage.

6. Brake Type and Design: Different brake types, such as electromagnetic brakes or spring-loaded brakes, offer specific advantages and considerations. The choice of brake type should align with the requirements of the application, taking into account factors such as braking torque, response time, and reliability. The design features of the brake, such as braking surface area, cooling methods, and wear indicators, should also be evaluated to ensure efficient and long-lasting braking performance.

7. Regulatory and Safety Standards: Compliance with applicable regulatory and safety standards is crucial when selecting a brake motor. Depending on the industry and application, specific standards and certifications may be required. It is essential to choose a brake motor that meets the necessary standards and safety requirements to ensure the protection of personnel, equipment, and compliance with legal obligations.

8. Cost and Lifecycle Considerations: Finally, the cost-effectiveness and lifecycle considerations should be evaluated. This includes factors such as initial investment, maintenance requirements, expected lifespan, and availability of spare parts. It is important to strike a balance between upfront costs and long-term reliability, selecting a brake motor that offers a favorable cost-to-performance ratio and aligns with the expected lifecycle and maintenance budget.

Considering these factors when selecting a brake motor helps ensure that the chosen motor is well-suited for the intended task, provides reliable and efficient operation, and meets the specific requirements of the application. Proper evaluation and assessment of these factors contribute to the overall success and performance of the brake motor in its designated task.

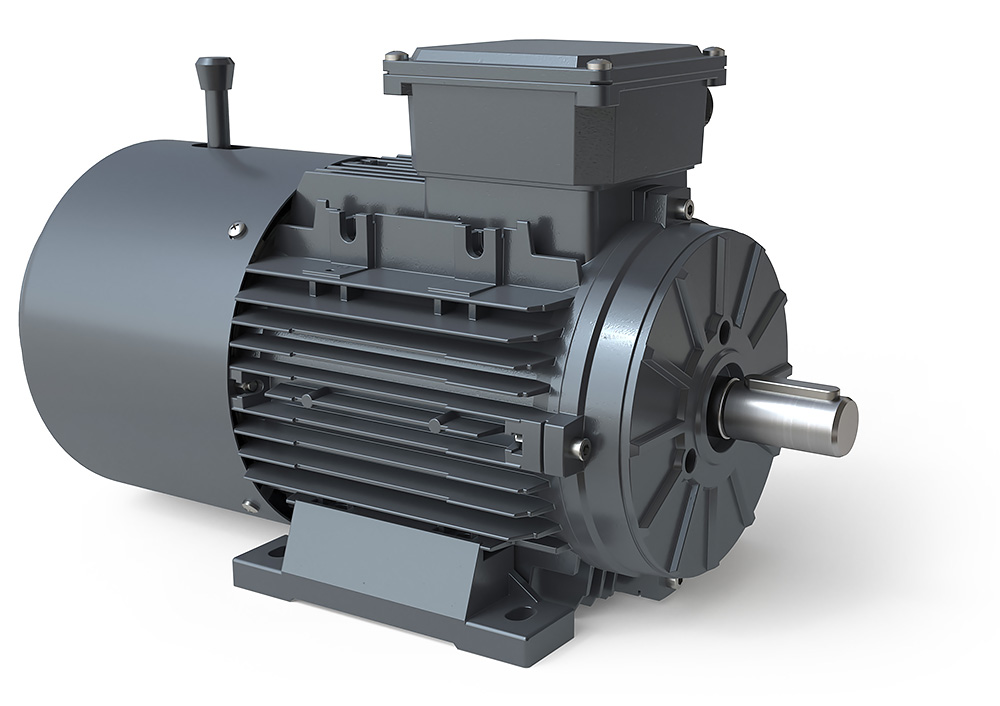

What is a brake motor and how does it operate?

A brake motor is a type of electric motor that incorporates a mechanical braking system. It is designed to provide both motor power and braking functionality in a single unit. The brake motor is commonly used in applications where rapid and precise stopping or holding of loads is required. Here’s a detailed explanation of what a brake motor is and how it operates:

A brake motor consists of two main components: the electric motor itself and a braking mechanism. The electric motor converts electrical energy into mechanical energy to drive a load. The braking mechanism, usually located at the non-drive end of the motor, provides the necessary braking force to stop or hold the load when the motor is turned off or power is cut off.

The braking mechanism in a brake motor typically employs one of the following types of brakes:

- Electromagnetic Brake: An electromagnetic brake is the most common type used in brake motors. It consists of an electromagnetic coil and a brake shoe or armature. When the motor is powered, the electromagnetic coil is energized, creating a magnetic field that attracts the brake shoe or armature. This releases the brake and allows the motor to rotate and drive the load. When the power is cut off or the motor is turned off, the electromagnetic coil is de-energized, and the brake shoe or armature is pressed against a stationary surface, creating friction and stopping the motor’s rotation.

- Mechanical Brake: Some brake motors use mechanical brakes, such as disc brakes or drum brakes. These brakes employ friction surfaces, such as brake pads or brake shoes, which are pressed against a rotating disc or drum attached to the motor shaft. When the motor is powered, the brake is disengaged, allowing the motor to rotate. When the power is cut off or the motor is turned off, a mechanical mechanism, such as a spring or a cam, engages the brake, creating friction and stopping the motor’s rotation.

The operation of a brake motor involves the following steps:

- Motor Operation: When power is supplied to the brake motor, the electric motor converts electrical energy into mechanical energy, which is used to drive the load. The brake is disengaged, allowing the motor shaft to rotate freely.

- Stopping or Holding: When the power is cut off or the motor is turned off, the braking mechanism is engaged. In the case of an electromagnetic brake, the electromagnetic coil is de-energized, and the brake shoe or armature is pressed against a stationary surface, creating friction and stopping the motor’s rotation. In the case of a mechanical brake, a mechanical mechanism engages the brake pads or shoes against a rotating disc or drum, creating friction and stopping the motor’s rotation.

- Release and Restart: To restart the motor, power is supplied again, and the braking mechanism is disengaged. In the case of an electromagnetic brake, the electromagnetic coil is energized, releasing the brake shoe or armature. In the case of a mechanical brake, the mechanical mechanism disengages the brake pads or shoes from the rotating disc or drum.

Brake motors are commonly used in applications that require precise stopping or holding of loads, such as cranes, hoists, conveyors, machine tools, and elevators. The incorporation of a braking system within the motor eliminates the need for external braking devices or additional components, simplifying the design and installation process. Brake motors enhance safety, efficiency, and control in industrial applications by providing reliable and rapid braking capabilities.

editor by CX 2024-04-24

China supplier 35-50km/H 10inch 48V-72V 500W-1000W Drum Brake Electric Hub Motor for Electric Scooter and Electric Motorcycle vacuum pump

Product Description

Used in scooter and motorcycle with high power

giving excellent balance capacity,comfortable,smooth and durable in use.

| working voltage | DC48V-DC96V |

| No load speed | 500rpm-700rpm |

| Rated power | 500W-1000W |

| efficiency | >=88% |

| Maximum torque | 70Nm-100Nm |

| Maximum speed | 35km/h-50km/h |

| Motor on gear | 200mm |

| Brake type | Drum/Disc brake |

| Color | Matt black/silver |

| Rim | 10 inch iron wheel |

| Applicable models | Electric motorcycle |

| Adaptive tire | English 3.0-10 3.5-10 |

| Metric 110 / 100-10 110 / 90-10 | |

| 90/90-10 100/90-10 | |

| Size | 46*27*31CM |

1. Q: Can I get samples before my formal order?

A: Yes, special sample services are available. And the sample cost can be relived once the formal order comes.

2. Q: How do you control the quality?

A: 1. Provide sample test report confirmation; 2. Seal sample confirmation. 3. Shoot production videos during the production process; 4. Send out test reports and test videos when the products are off-line; 5. Use foam cartons and woven bags for packaging, and the perfect packaging method ensures that the products are not damaged during transportation.

3. Q: Can I get a customize service?

A: Yes, ODM OEM services are available. (Appearance color, decal, power, etc. can be customized if the quantity can be above 50sets)

4. Q: What is the warranty time of your products?

A:The motor and controller are guaranteed for 18 months.

5. Q: How about payment terms and price terms?

A: Payment Terms: EXW,FOB,CNF/CFR,CIF,L/C, etc. Price Terms: Sample list 100%;Regular order 100% TT or 100% L/C or 30%TT,70%L/C.The specific payment method can be negotiated.

6. Q: What’s the approximate lead time?

A: After the advanced payment confirmed, normally 5 days for stock products,15 days for conventional models , and 30 days for special models. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Charge |

|---|---|

| Warranty: | 18 Mouths |

| Type: | Motor |

| Brake System: | Drum Brake/Disc Brake |

| Speed: | 35-50km/H |

| Supply Voltage: | DC48V-DC96V |

| Samples: |

US$ 56/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do brake motors handle variations in brake torque and response time?

Brake motors are designed to handle variations in brake torque and response time to ensure reliable and efficient braking performance. These variations can arise due to different operating conditions, load characteristics, or specific application requirements. Here’s a detailed explanation of how brake motors handle variations in brake torque and response time:

- Brake Design and Construction: The design and construction of brake systems in brake motors play a crucial role in handling variations in brake torque and response time. Brake systems typically consist of brake pads or shoes that press against a brake disc or drum to generate frictional forces and provide braking action. The materials used for the brake components, such as brake linings, can be selected or designed to offer a wide range of torque capacities and response characteristics. By choosing the appropriate materials and optimizing the brake system design, brake motors can accommodate variations in torque requirements and response times.

- Brake Control Mechanisms: Brake motors employ different control mechanisms to manage brake torque and response time. These mechanisms can be mechanical, electrical, or a combination of both. Mechanical control mechanisms often utilize springs or levers to apply and release the brake, while electrical control mechanisms rely on electromagnets or solenoids to engage or disengage the brake. The control mechanisms can be adjusted or configured to modulate the brake torque and response time based on the specific needs of the application.

- Brake Torque Adjustments: Brake motors may offer provisions for adjusting the brake torque to accommodate variations in load requirements. This can be achieved through the selection of different brake linings or by adjusting the spring tension or magnetic force within the brake system. By modifying the brake torque, brake motors can provide the necessary braking force to meet the demands of different operating conditions or load characteristics.

- Response Time Optimization: Brake motors can be engineered to optimize the response time of the braking system. The response time refers to the time it takes for the brake to engage or disengage once the control signal is applied. Several factors can influence the response time, including the design of the control mechanism, the characteristics of the brake linings, and the braking system’s overall dynamics. By fine-tuning these factors, brake motors can achieve faster or slower response times as required by the application, ensuring effective and timely braking action.

- Electronic Control Systems: In modern brake motors, electronic control systems are often employed to enhance the flexibility and precision of brake torque and response time adjustments. These systems utilize sensors, feedback mechanisms, and advanced control algorithms to monitor and regulate the brake performance. Electronic control allows for real-time adjustments and precise control of the brake torque and response time, making brake motors more adaptable to variations in operating conditions and load requirements.

By combining appropriate brake design and construction, control mechanisms, torque adjustments, response time optimization, and electronic control systems, brake motors can effectively handle variations in brake torque and response time. This enables them to provide reliable and efficient braking performance across a wide range of operating conditions, load characteristics, and application requirements.

How do manufacturers ensure the quality and reliability of brake motors?

Manufacturers employ various processes and measures to ensure the quality and reliability of brake motors. These processes involve rigorous testing, adherence to industry standards, quality control procedures, and continuous improvement initiatives. Here’s a detailed explanation of how manufacturers ensure the quality and reliability of brake motors:

- Design and Engineering: Manufacturers invest considerable effort in the design and engineering phase of brake motors. They employ experienced engineers and designers who follow industry best practices and utilize advanced design tools to develop motors with robust and reliable braking systems. Thorough analysis, simulations, and prototyping are conducted to optimize the motor’s performance, efficiency, and safety features.

- Material Selection: High-quality materials are chosen for the construction of brake motors. Manufacturers carefully select components such as motor windings, brake discs, brake pads, and housing materials to ensure durability, heat resistance, and optimal friction characteristics. The use of quality materials enhances the motor’s reliability and contributes to its long-term performance.

- Manufacturing Processes: Stringent manufacturing processes are implemented to ensure consistent quality and reliability. Manufacturers employ advanced machinery and automation techniques for precision assembly and production. Strict quality control measures are applied at each stage of manufacturing to detect and rectify any defects or deviations from specifications.

- Testing and Quality Assurance: Brake motors undergo comprehensive testing and quality assurance procedures before they are released to the market. These tests include performance testing, load testing, endurance testing, and environmental testing. Manufacturers verify that the motors meet or exceed industry standards and performance specifications. Additionally, they conduct safety tests to ensure compliance with applicable safety regulations and standards.

- Certifications and Compliance: Manufacturers seek certifications and compliance with relevant industry standards and regulations. This may include certifications such as ISO 9001 for quality management systems or certifications specific to the motor industry, such as IEC (International Electrotechnical Commission) standards. Compliance with these standards demonstrates the manufacturer’s commitment to producing high-quality and reliable brake motors.

- Quality Control and Inspection: Manufacturers implement robust quality control processes throughout the production cycle. This includes inspection of raw materials, in-process inspections during manufacturing, and final inspections before shipment. Quality control personnel conduct visual inspections, dimensional checks, and performance evaluations to ensure that each brake motor meets the specified quality criteria.

- Continuous Improvement: Manufacturers prioritize continuous improvement initiatives to enhance the quality and reliability of brake motors. They actively seek customer feedback, monitor field performance, and conduct post-production evaluations to identify areas for improvement. This feedback loop helps manufacturers refine their designs, manufacturing processes, and quality control procedures, leading to increased reliability and customer satisfaction.

- Customer Support and Warranty: Manufacturers provide comprehensive customer support and warranty programs for their brake motors. They offer technical assistance, troubleshooting guides, and maintenance recommendations to customers. Warranty coverage ensures that any manufacturing defects or malfunctions are addressed promptly, bolstering customer confidence in the quality and reliability of the brake motors.

By employing robust design and engineering processes, meticulous material selection, stringent manufacturing processes, comprehensive testing and quality assurance procedures, certifications and compliance with industry standards, rigorous quality control and inspection measures, continuous improvement initiatives, and dedicated customer support and warranty programs, manufacturers ensure the quality and reliability of brake motors. These measures contribute to the production of high-performance motors that meet the safety, durability, and performance requirements of industrial and manufacturing applications.

What industries and applications commonly use brake motors?

Brake motors find wide-ranging applications across various industries that require controlled stopping, load holding, and precise positioning. Here’s a detailed overview of the industries and applications commonly using brake motors:

1. Material Handling: Brake motors are extensively used in material handling equipment such as cranes, hoists, winches, and conveyors. These applications require precise control over the movement of heavy loads, and brake motors provide efficient stopping and holding capabilities, ensuring safe and controlled material handling operations.

2. Elevators and Lifts: The vertical movement of elevators and lifts demands reliable braking systems to hold the load in position during power outages or when not actively driving the movement. Brake motors are employed in elevator systems to ensure passenger safety and prevent unintended movement or freefall of the elevator car.

3. Machine Tools: Brake motors are used in machine tools such as lathes, milling machines, drilling machines, and grinders. These applications often require precise positioning and rapid stopping of rotating spindles or cutting tools. Brake motors provide the necessary control and safety measures for efficient machining operations.

4. Conveyor Systems: Conveyor systems in industries like manufacturing, logistics, and warehouses utilize brake motors to achieve accurate control over the movement of goods. Brake motors enable smooth acceleration, controlled deceleration, and precise stopping of conveyor belts, ensuring proper material flow and minimizing the risk of collisions or product damage.

5. Crushers and Crushers: In industries such as mining, construction, and aggregates, brake motors are commonly used in crushers and crushers. These machines require rapid and controlled stopping to prevent damage caused by excessive vibration or unbalanced loads. Brake motors provide the necessary braking force to halt the rotation of crusher components quickly.

6. Robotics and Automation: Brake motors play a vital role in robotics and automation systems that require precise movement control and positioning. They are employed in robotic arms, automated assembly lines, and pick-and-place systems to achieve accurate and repeatable movements, ensuring seamless operation and high productivity.

7. Printing and Packaging: Brake motors are utilized in printing presses, packaging machines, and labeling equipment. These applications require precise control over the positioning of materials, accurate registration, and consistent stopping during printing or packaging processes. Brake motors ensure reliable performance and enhance the quality of printed and packaged products.

8. Textile Machinery: Brake motors are commonly found in textile machinery such as spinning machines, looms, and textile printing equipment. These applications demand precise control over yarn tension, fabric movement, and position holding. Brake motors offer the necessary braking force and control for smooth textile manufacturing processes.

9. Food Processing: Brake motors are employed in food processing equipment, including mixers, slicers, extruders, and dough handling machines. These applications require precise control over mixing, slicing, and shaping processes, as well as controlled stopping to ensure operator safety and prevent product wastage.

These are just a few examples, and brake motors are utilized in numerous other industries and applications where controlled stopping, load holding, and precise positioning are essential. The versatility and reliability of brake motors make them a preferred choice in various industrial sectors, contributing to enhanced safety, productivity, and operational control.

editor by CX 2024-04-22

China Good quality 8 Inch DIY Ebs Brake Electric Scooter Kits Gearless Hub Motor Wheel with Full Accessories vacuum pump brakes

Product Description

Quick Details

Place of Origin: ZheJiang , China (Mainland)

Brand Name: ETECH

Certification: CE

Commutation: Brushless

Protect Feature: Waterproof

Continuous Current(A): 1.3-12.4A

Efficiency: IE 4

Noise: 55db

Motor type: Gearess Brushless DC Motor

Usage: Home Appliance, robotics, electric scooter etc.

Speed(RPM): Max 1200(r/min)

Voltage: DC 24V/36V/48V

Power: MAX:400W

Speed: MAX:28-35km/h

Diameter with tire: 200mm

Brake: EBS brake

Tire: hollow tire

Weight: 4KG with tire

Cable: 3 motor phase with 5 hall sensor

The kits including:

hub motor wheel

controller

LCD display

EBS brake handle

thumb throttle

We provide both single and double shaft version

If you are building robotics or Automated Xihu (West Lake) Dis.d Vehicles, we provide this motor with built-in 1571ppr encoder, price is different, plz contact us for more information

We have motor from min 3 inch(70mm) to max 15 inch (380mm), all waterproof and low noise, high quality with good price

FAQ

1. Factory or trader? We are factory, the source of the supply chain.

2. Delivery time? – Sample: 5 days. Bulk order: 7-25 days.

3. Why choose us?

* Factory Price & 24/7 after-sale services.

* 3 more quality test before products leave factory.

* Long life, durable and multi-application.

* Self Protection system avoids damage when overloaded or abruptly stoped.

* High efficiency and high torque available in small diameter.

* All products are made according to ISO 9001, CE, ROHS, CCC, UL and GS requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial, Household Appliances, Car, Industrial, Household Appliances, Car |

|---|---|

| Operating Speed: | Adjust Speed |

| Excitation Mode: | SACS |

| Function: | Driving |

| Casing Protection: | Open Type |

| Number of Poles: | 20 |

| Samples: |

US$ 140/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety precautions should be followed when working with brake motors?

Working with brake motors requires adherence to specific safety precautions to ensure the well-being of personnel and the proper functioning of the equipment. Brake motors involve electrical components and potentially hazardous mechanical operations, so it is essential to follow established safety guidelines. Here’s a detailed explanation of the safety precautions that should be followed when working with brake motors:

- Qualified Personnel: Only trained and qualified individuals should be allowed to work with brake motors. They should have a thorough understanding of electrical systems, motor operation, and safety procedures. Proper training ensures that personnel are familiar with the specific risks associated with brake motors and know how to handle them safely.

- Power Isolation: Before performing any maintenance or repair tasks on a brake motor, it is crucial to isolate the power supply to the motor. This can be achieved by disconnecting the power source and following lockout/tagout procedures to prevent accidental re-energization. Power isolation eliminates the risk of electric shock and allows safe access to the motor without the danger of unexpected startup.

- Personal Protective Equipment (PPE): When working with brake motors, appropriate personal protective equipment should be worn. This may include safety glasses, gloves, protective clothing, and hearing protection, depending on the specific hazards present. PPE helps safeguard against potential hazards such as flying debris, electrical shocks, and excessive noise, providing an additional layer of protection for personnel.

- Proper Ventilation: Adequate ventilation should be ensured when working with brake motors, especially in indoor environments. Ventilation helps dissipate heat generated by the motor and prevents the buildup of potentially harmful fumes or gases. Proper ventilation reduces the risk of overheating and improves air quality, creating a safer working environment.

- Safe Lifting and Handling: Brake motors can be heavy and require proper lifting and handling techniques to prevent injuries. When moving or installing a motor, personnel should use appropriate lifting equipment, such as cranes or hoists, and follow safe lifting practices. It is important to avoid overexertion, use proper body mechanics, and seek assistance when necessary to prevent strains or accidents.

- Protection Against Moving Parts: Brake motors may have rotating or moving parts that pose a risk of entanglement or crushing injuries. Guards and protective covers should be in place to prevent accidental contact with these hazardous areas. Personnel should never reach into or attempt to adjust the motor while it is in operation or without proper lockout/tagout procedures in place.

- Maintenance and Inspection: Regular maintenance and inspection of brake motors are essential for their safe and reliable operation. Maintenance tasks should only be performed by qualified personnel following manufacturer recommendations. Before conducting any maintenance or inspection, the motor should be properly isolated and de-energized. Visual inspections, lubrication, and component checks should be carried out according to the motor’s maintenance schedule to identify and address any potential issues before they escalate.

- Follow Manufacturer Guidelines: It is crucial to follow the manufacturer’s guidelines and recommendations when working with brake motors. This includes adhering to installation procedures, operating instructions, and maintenance practices specified by the manufacturer. Manufacturers provide specific safety instructions and precautions that are tailored to their equipment, ensuring safe and efficient operation when followed meticulously.

- Training and Awareness: Ongoing training and awareness programs should be implemented to keep personnel updated on safety practices and potential hazards associated with brake motors. This includes providing clear instructions, conducting safety meetings, and promoting a safety-conscious culture. Personnel should be encouraged to report any safety concerns or incidents to ensure continuous improvement of safety measures.

By following these safety precautions, personnel can mitigate risks and create a safer working environment when dealing with brake motors. Adhering to proper procedures, using appropriate PPE, ensuring power isolation, practicing safe lifting and handling, protecting against moving parts, conducting regular maintenance and inspections, and staying informed about manufacturer guidelines are all crucial steps in maintaining a safe and efficient work environment when working with brake motors.

What maintenance practices are essential for extending the lifespan of a brake motor?

Maintaining a brake motor properly is crucial for extending its lifespan and ensuring optimal performance. Regular maintenance practices help prevent premature wear, identify potential issues, and address them promptly. Here are some essential maintenance practices for extending the lifespan of a brake motor:

- Cleanliness: Keeping the brake motor clean is important to prevent the accumulation of dirt, dust, or debris that can affect its performance. Regularly inspect the motor and clean it using appropriate cleaning methods and materials, ensuring that the power is disconnected before performing any cleaning tasks.

- Lubrication: Proper lubrication of the brake motor’s moving parts is essential to minimize friction and reduce wear and tear. Follow the manufacturer’s recommendations regarding the type of lubricant to use and the frequency of lubrication. Ensure that the lubrication points are accessible and apply the lubricant in the recommended amounts.

- Inspection: Regular visual inspections of the brake motor are necessary to identify any signs of damage, loose connections, or abnormal wear. Check for any loose or damaged components, such as bolts, cables, or connectors. Inspect the brake pads or discs for wear and ensure they are properly aligned. If any issues are detected, take appropriate action to address them promptly.

- Brake Adjustment: Periodically check and adjust the brake mechanism of the motor to ensure it maintains proper braking performance. This may involve adjusting the brake pads, ensuring proper clearance, and verifying that the braking force is sufficient. Improper brake adjustment can lead to excessive wear, reduced stopping power, or safety hazards.

- Temperature Monitoring: Monitoring the operating temperature of the brake motor is important to prevent overheating and thermal damage. Ensure that the motor is not subjected to excessive ambient temperatures or overloaded conditions. If the motor becomes excessively hot, investigate the cause and take corrective measures, such as improving ventilation or reducing the load.

- Vibration Analysis: Periodic vibration analysis can help detect early signs of mechanical problems or misalignment in the brake motor. Using specialized equipment or vibration monitoring systems, measure and analyze the motor’s vibration levels. If abnormal vibrations are detected, investigate and address the underlying issues to prevent further damage.

- Electrical Connections: Regularly inspect the electrical connections of the brake motor to ensure they are secure and free from corrosion. Loose or faulty connections can lead to power issues, motor malfunctions, or electrical hazards. Tighten any loose connections and clean any corrosion using appropriate methods and materials.

- Testing and Calibration: Perform periodic testing and calibration of the brake motor to verify its performance and ensure it operates within the specified parameters. This may involve conducting load tests, verifying braking force, or checking the motor’s speed and torque. Follow the manufacturer’s guidelines or consult with qualified technicians for proper testing and calibration procedures.

- Documentation and Record-keeping: Maintain a record of all maintenance activities, inspections, repairs, and any relevant information related to the brake motor. This documentation helps track the maintenance history, identify recurring issues, and plan future maintenance tasks effectively. It also serves as a reference for warranty claims or troubleshooting purposes.

- Professional Servicing: In addition to regular maintenance tasks, consider scheduling professional servicing and inspections by qualified technicians. They can perform comprehensive checks, identify potential issues, and perform specialized maintenance procedures that require expertise or specialized tools. Professional servicing can help ensure thorough maintenance and maximize the lifespan of the brake motor.

By following these essential maintenance practices, brake motor owners can enhance the lifespan of the motor, reduce the risk of unexpected failures, and maintain its optimal performance. Regular maintenance not only extends the motor’s lifespan but also contributes to safe operation, energy efficiency, and overall reliability.

How do brake motors ensure controlled and rapid stopping of rotating equipment?

Brake motors are designed to ensure controlled and rapid stopping of rotating equipment by employing specific braking mechanisms. These mechanisms are integrated into the motor to provide efficient and precise stopping capabilities. Here’s a detailed explanation of how brake motors achieve controlled and rapid stopping:

1. Electromagnetic Brakes: Many brake motors utilize electromagnetic brakes as the primary braking mechanism. These brakes consist of an electromagnetic coil and a brake disc or plate. When the power to the motor is cut off or the motor is de-energized, the electromagnetic coil generates a magnetic field that attracts the brake disc or plate, creating friction and halting the rotation of the motor shaft. The strength of the magnetic field and the design of the brake determine the stopping torque and speed, allowing for controlled and rapid stopping of the rotating equipment.

2. Spring-Loaded Brakes: Some brake motors employ spring-loaded brakes. These brakes consist of a spring that applies pressure on the brake disc or plate to create friction and stop the rotation. When the power is cut off or the motor is de-energized, the spring is released, pressing the brake disc against a stationary surface and generating braking force. The spring-loaded mechanism ensures quick engagement of the brake, resulting in rapid stopping of the rotating equipment.

3. Dynamic Braking: Dynamic braking is another technique used in brake motors to achieve controlled stopping. It involves converting the kinetic energy of the rotating equipment into electrical energy, which is dissipated as heat through a resistor or regenerative braking system. When the power is cut off or the motor is de-energized, the motor acts as a generator, and the electrical energy generated by the rotating equipment is converted into heat through the braking system. This dissipation of energy slows down and stops the rotation of the equipment in a controlled manner.

4. Control Systems: Brake motors are often integrated with control systems that enable precise control over the braking process. These control systems allow for adjustable braking torque, response time, and braking profiles, depending on the specific requirements of the application. By adjusting these parameters, operators can achieve the desired level of control and stopping performance, ensuring both safety and operational efficiency.

5. Coordinated Motor and Brake Design: Brake motors are designed with careful consideration of the motor and brake compatibility. The motor’s characteristics, such as torque, speed, and power rating, are matched with the braking system’s capabilities to ensure optimal performance. This coordinated design ensures that the brake can effectively stop the motor within the desired time frame and with the necessary braking force, achieving controlled and rapid stopping of the rotating equipment.

Overall, brake motors employ electromagnetic brakes, spring-loaded brakes, dynamic braking, and control systems to achieve controlled and rapid stopping of rotating equipment. These braking mechanisms, combined with coordinated motor and brake design, enable precise control over the stopping process, ensuring the safety of operators, protecting equipment from damage, and maintaining operational efficiency.

editor by CX 2024-04-12

China wholesaler 16 Inch 60V 72V 2000W 3000W Brushless Gearless Aluminum Alloy Electric Motorcycle Bicycle Hub Motor with Disc Brake and Sprocket vacuum pump connector

Product Description

2.Product introduction

Used in scooter and motorcycle with high power

giving excellent balance capacity,comfortable,smooth and durable in use.

| working voltage | DC48V-DC72V |

| No load speed | 500rpm-900rpm |

| Rated power | 1200W-5000W |

| Efficiency | >=90% |

| Maximum torque | 180Nm-260Mn |

| Maximum speed | 60km/h-90km/h |

| Motor on gear | 200mm 230mm |

| Brake type | Disc brake |

| Color | Matt black |

| Rim | 16 inch iron wheel |

| Applicable models | Electric motorcycle |

| Adaptive tire | English 5.0-1.6 |

| Metric 110/70-16 120/70-16 | |

| 130/70-16 |

1. Q: Can I get samples before my formal order?

A: Yes, special sample services are available. And the sample cost can be relived once the formal order comes.

2. Q: Could you tell me what the packing looks like?

A: CKD, SKD, CBU

3. Q: How do you control the quality?

A: All the materils are tested before they enter into our factory; Professional staffs will be in charge of the inspection works during the production process; Finial inspections will be arrange before delivery.

4. Q: Can I get a customize service?

A: Yes, ODM OEM services are available. (Appearance color, decal, power, etc. can be customized if the quantity can be above 50sets)

5. Q: What is the warranty time of your products?

A: Different product types are with different warranty times. (Our team will offer the details for you accordingly.)

6. Q: How about payment terms and price terms?

A: Payment Terms: EXW, FOB Available. Price Terms: New customers: sample list 100%, large order 50% deposit, 50% before shipment; Regular customers: 30% deposit, 70% before delivery, 30% TT and 70% L/C are acceptable.

7. Q: What’s the approximate lead time?

A: After the advanced payment confirmed, normally 30 days for conventional models , and 45 days for special models.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Charge |

|---|---|

| Warranty: | 18 Mouths |

| Type: | Motor |

| Brake System: | Disc Brake |

| Speed: | 60-90km/H |

| Supply Voltage: | DC48V-DC72V |

| Samples: |

US$ 249/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do brake motors impact the overall productivity of manufacturing processes?