Product Description

Company Introduction

DAJI GROUP. ZHangZhouG CHINAMFG ELECTRIC MOTOR Co., Ltd, is professional enaged in electric motor manufacturing for 30 years since 1988. The headquarters is located in ZheJiang city, group with 4 manufacturing bases in zHangZhoug and ZheJiang , has more than 300 national sales centers and special agencies, and exported to more than 50 countries and regions.

Factory Advantages

1. 30 years history

2. Competitive price

3. Guaranteed quality

4. Fast delivery time: normal models about 15-20 days , unusual models about 30 days

5. 100% testing after every process, 100% raw materials are selective

6. High efficiency

7. Low noise

8. Long life

9. Power saving

10. Slight vibration

11. It is newly designed in conformity with the relevant rules of IEC standards

12. Professional Service

13. Warranty: 12 months from date of delivery

14. Main Market: South America, Europe, Middle East, Southest Asia, Africa and so on

15. We have certificates for CE, CCC, ISO9001, SGS and so on

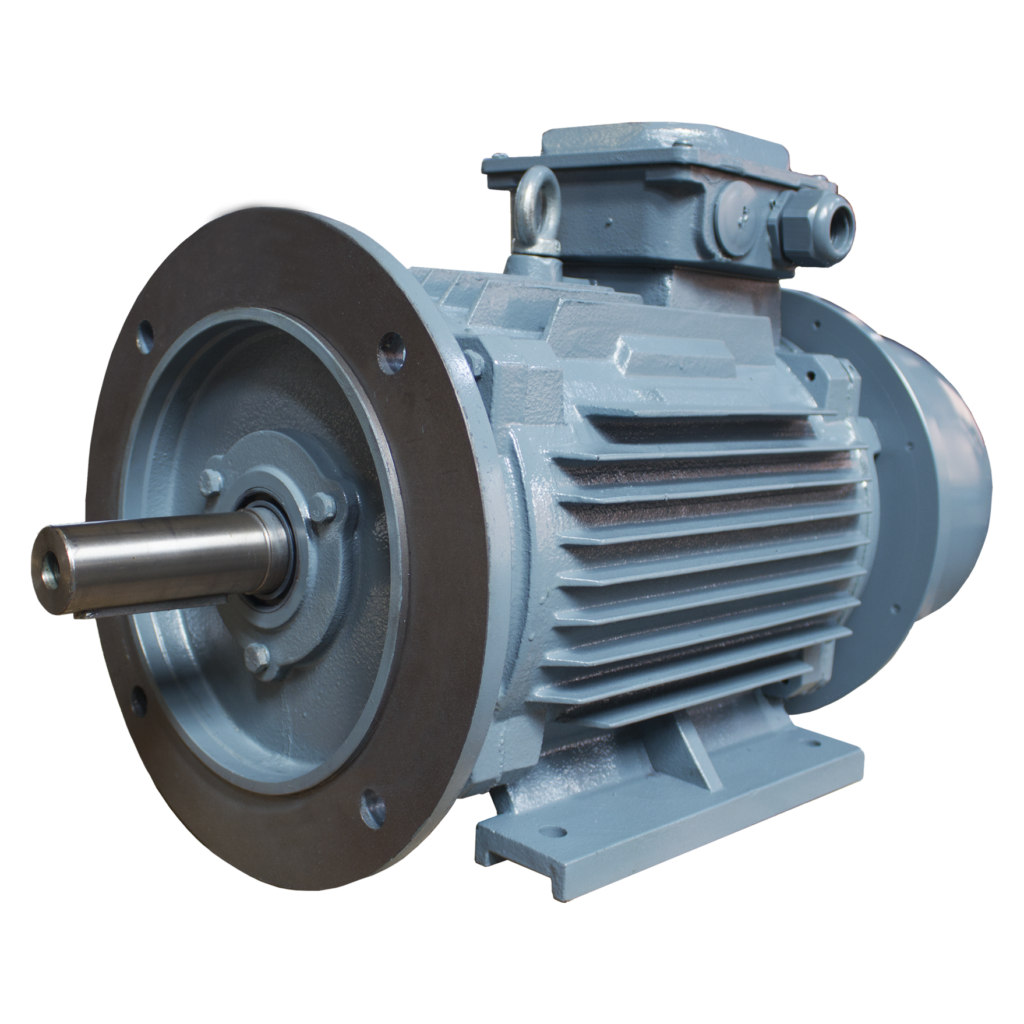

Product Introduction

The series of YEJ2 motor is the improvement product of YEJ series motor, which can realize rapid braking after the motor loses power. And the electrical performance, installation size, protection class and insulation class are consistent with the requirements of YE2 series motor.

It is applicable to all kinds of machine tools, printing machinery, air forging press, transportation machinery, food machinery, civil engineering machinery and other machinery that require quick stop, accurate positioning, reciprocating operation and prevent sliding. And it is used as spindle drive and auxiliary drive in these machinery.

| YEJ2 Series Electromagnetic Brake Three- Phase Asynchronous Motor | |

| 1). Frame: | 80 – 225 mm |

| 2). Power: | 0.55 – 45 kW |

| 3). Voltage: | 380 V, or Customized |

| 4). Frequency: | 50 Hz |

| 5). Shell: | cast iron body, aluminum body |

| 6). Pole: | 2, 4, 6, 8 |

| 7). Protection degree: | IP44 (motor) & IP23 (brake) |

| 8). Insulation class: | F |

| 9). Cooling method: | IC411 |

| 10). Duty Type: | S1 |

| 11).Certificates: | CE, CCC, ISO9001, SGS and so on |

Working Condition: ambient temperature is -15oC to 40oC, and below 1000 CHINAMFG above sea level

Mounting Type:

Conventional mounting type and suitable frame size are given in following table(with “√”)

| Frame | Basic Type | Derived Type | |||||||||||||

| B3 | B5 | B6 | B7 | B8 | B35 | V1 | V3 | V5 | V6 | V15 | V18 | V35 | V36 | V37 | |

| 80~160 | √ | √ | √ | √ | √ | √ | – | – | – | – | – | – | – | – | – |

| 180~225 | √ | √ | – | – | – | √ | – | – | – | – | – | – | – | – | – |

FAQ:

Q: What is your delivery time?

A: Within 20-25 days after receiving deposit.

Q: Do you offer OEM service?

A: Yes. We accept OEM service.

Q: What is your MOQ of this item ?

A: 10 PCS per item.

Q: Can we type our brand on it?

A: Yes, of course.

Q: Where is your loading port ?

A: HangZhou Port, ZheJiang Port, China.

Q: What is your production capacity?

A: About 1000 PCS per day.

Ordering Instructions

1. Please indicate the fram size, power, synchronous speed, voltage, frequency, install measurements, inlet cable entrance type and direction of rotation etc.

2. If have special request, such as the voltage, frequency, protection degree, duplex shaft, direction of rotation, temperature monitoring device, install measurements, bearing oil discharge device and so on, please indicate in details in the ordering contract and CHINAMFG technical agreement if necessary.

3. When ordering other series of motor and derived motor in the sample, please follow this instruction without further notice, thank you for your cooperation!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Low Speed |

| Number of Stator: | Three-Phase |

| Casing Protection: | Closed Type |

| Number of Poles: | 8 |

| Starting Mode: | y-δ Starting |

| Customization: |

Available

|

|

|---|

How do brake motors ensure smooth and controlled movement in equipment?

Brake motors play a crucial role in ensuring smooth and controlled movement in equipment by providing reliable braking functionality. They work in coordination with the motor and other control systems to achieve precise control over the motion of the equipment. Here’s a detailed explanation of how brake motors ensure smooth and controlled movement in equipment:

- Braking Capability: Brake motors are specifically designed to provide effective braking capability. When the power to the motor is cut off or when a braking signal is applied, the brake system engages, generating frictional forces that slow down and bring the equipment to a controlled stop. The brake torque generated by the motor helps prevent coasting or unintended movement, ensuring smooth and controlled deceleration.

- Quick Response Time: Brake motors are engineered to have a quick response time, meaning that the brake engages rapidly once the control signal is applied. This quick response time allows for prompt and precise control over the movement of the equipment. By minimizing the delay between the initiation of the braking action and the actual engagement of the brake, brake motors contribute to smooth and controlled movement.

- Adjustable Brake Torque: Brake motors often offer the ability to adjust the brake torque to suit the specific requirements of the equipment and application. The brake torque can be tailored to the load characteristics and operating conditions to achieve optimal braking performance. By adjusting the brake torque, brake motors ensure that the equipment decelerates smoothly and consistently, avoiding abrupt stops or jerky movements.

- Brake Release Mechanisms: In addition to providing braking action, brake motors incorporate mechanisms to release the brake when the equipment needs to resume motion. These release mechanisms can be controlled manually or automatically, depending on the application. The controlled release of the brake ensures that the equipment starts moving smoothly and gradually, allowing for controlled acceleration.

- Integration with Control Systems: Brake motors are integrated into the overall control systems of the equipment to achieve coordinated and synchronized movement. They work in conjunction with motor control devices, such as variable frequency drives (VFDs) or servo systems, to precisely control the speed, acceleration, and deceleration of the equipment. By seamlessly integrating with the control systems, brake motors contribute to the smooth and controlled movement of the equipment.

- Compliance with Safety Standards: Brake motors are designed and manufactured in compliance with safety standards and regulations. They undergo rigorous testing and quality control measures to ensure reliable and consistent braking performance. By adhering to safety standards, brake motors help prevent sudden or uncontrolled movements that could pose a safety risk and ensure the equipment operates within acceptable limits.

By providing effective braking capability, quick response time, adjustable brake torque, release mechanisms, integration with control systems, and compliance with safety standards, brake motors ensure smooth and controlled movement in equipment. They enable precise control over the deceleration, stopping, and starting of the equipment, enhancing operational efficiency, safety, and overall performance.

How do brake motors contribute to the efficiency of conveyor systems and material handling?

Brake motors play a crucial role in enhancing the efficiency of conveyor systems and material handling operations. They provide several advantages that improve the overall performance and productivity of these systems. Here’s a detailed explanation of how brake motors contribute to the efficiency of conveyor systems and material handling:

- Precise Control: Brake motors offer precise control over the movement of conveyor systems. The braking mechanism allows for quick and accurate stopping, starting, and positioning of the conveyor belt or other material handling components. This precise control ensures efficient operation, minimizing the time and effort required to handle materials and reducing the risk of damage or accidents.

- Speed Regulation: Brake motors can regulate the speed of conveyor systems, allowing operators to adjust the conveying speed according to the specific requirements of the materials being handled. This speed control capability enables efficient material flow, optimizing production processes and preventing bottlenecks or congestion. It also contributes to better synchronization with upstream or downstream processes, improving overall system efficiency.

- Load Handling: Brake motors are designed to handle varying loads encountered in material handling applications. They provide the necessary power and torque to move heavy loads along the conveyor system smoothly and efficiently. The braking mechanism ensures safe and controlled stopping even with substantial loads, preventing excessive wear or damage to the system and facilitating efficient material transfer.

- Energy Efficiency: Brake motors are engineered for energy efficiency, contributing to cost savings and sustainability in material handling operations. They are designed to minimize energy consumption during operation by optimizing motor efficiency, reducing heat losses, and utilizing regenerative braking techniques. Energy-efficient brake motors help lower electricity consumption, resulting in reduced operating costs and a smaller environmental footprint.

- Safety Enhancements: Brake motors incorporate safety features that enhance the efficiency of conveyor systems and material handling by safeguarding personnel and equipment. They are equipped with braking systems that provide reliable stopping power, preventing unintended motion or runaway loads. Emergency stop functionality adds an extra layer of safety, allowing immediate halting of the system in case of emergencies or hazards, thereby minimizing the potential for accidents and improving overall operational efficiency.

- Reliability and Durability: Brake motors are constructed to withstand the demanding conditions of material handling environments. They are designed with robust components and built-in protection features to ensure reliable operation even in harsh or challenging conditions. The durability of brake motors reduces downtime due to motor failures or maintenance issues, resulting in improved system efficiency and increased productivity.

- Integration and Automation: Brake motors can be seamlessly integrated into automated material handling systems, enabling efficient and streamlined operations. They can be synchronized with control systems and sensors to optimize material flow, automate processes, and enable efficient sorting, routing, or accumulation of items. This integration and automation capability enhances system efficiency, reduces manual intervention, and enables real-time monitoring and control of the material handling process.

- Maintenance and Serviceability: Brake motors are designed for ease of maintenance and serviceability, which contributes to the overall efficiency of conveyor systems and material handling operations. They often feature modular designs that allow quick and easy replacement of components, minimizing downtime during maintenance or repairs. Accessible lubrication points, inspection ports, and diagnostic features simplify routine maintenance tasks, ensuring that the motors remain in optimal working condition and maximizing system uptime.

By providing precise control, speed regulation, reliable load handling, energy efficiency, safety enhancements, durability, integration with automation systems, and ease of maintenance, brake motors significantly contribute to the efficiency of conveyor systems and material handling operations. Their performance and features optimize material flow, reduce downtime, enhance safety, lower operating costs, and improve overall productivity in a wide range of industries and applications.

What industries and applications commonly use brake motors?

Brake motors find wide-ranging applications across various industries that require controlled stopping, load holding, and precise positioning. Here’s a detailed overview of the industries and applications commonly using brake motors:

1. Material Handling: Brake motors are extensively used in material handling equipment such as cranes, hoists, winches, and conveyors. These applications require precise control over the movement of heavy loads, and brake motors provide efficient stopping and holding capabilities, ensuring safe and controlled material handling operations.

2. Elevators and Lifts: The vertical movement of elevators and lifts demands reliable braking systems to hold the load in position during power outages or when not actively driving the movement. Brake motors are employed in elevator systems to ensure passenger safety and prevent unintended movement or freefall of the elevator car.

3. Machine Tools: Brake motors are used in machine tools such as lathes, milling machines, drilling machines, and grinders. These applications often require precise positioning and rapid stopping of rotating spindles or cutting tools. Brake motors provide the necessary control and safety measures for efficient machining operations.

4. Conveyor Systems: Conveyor systems in industries like manufacturing, logistics, and warehouses utilize brake motors to achieve accurate control over the movement of goods. Brake motors enable smooth acceleration, controlled deceleration, and precise stopping of conveyor belts, ensuring proper material flow and minimizing the risk of collisions or product damage.

5. Crushers and Crushers: In industries such as mining, construction, and aggregates, brake motors are commonly used in crushers and crushers. These machines require rapid and controlled stopping to prevent damage caused by excessive vibration or unbalanced loads. Brake motors provide the necessary braking force to halt the rotation of crusher components quickly.

6. Robotics and Automation: Brake motors play a vital role in robotics and automation systems that require precise movement control and positioning. They are employed in robotic arms, automated assembly lines, and pick-and-place systems to achieve accurate and repeatable movements, ensuring seamless operation and high productivity.

7. Printing and Packaging: Brake motors are utilized in printing presses, packaging machines, and labeling equipment. These applications require precise control over the positioning of materials, accurate registration, and consistent stopping during printing or packaging processes. Brake motors ensure reliable performance and enhance the quality of printed and packaged products.

8. Textile Machinery: Brake motors are commonly found in textile machinery such as spinning machines, looms, and textile printing equipment. These applications demand precise control over yarn tension, fabric movement, and position holding. Brake motors offer the necessary braking force and control for smooth textile manufacturing processes.

9. Food Processing: Brake motors are employed in food processing equipment, including mixers, slicers, extruders, and dough handling machines. These applications require precise control over mixing, slicing, and shaping processes, as well as controlled stopping to ensure operator safety and prevent product wastage.

These are just a few examples, and brake motors are utilized in numerous other industries and applications where controlled stopping, load holding, and precise positioning are essential. The versatility and reliability of brake motors make them a preferred choice in various industrial sectors, contributing to enhanced safety, productivity, and operational control.

editor by CX 2024-04-09